Fault 1: The defrost heating tube does not heat up, and the evaporator is severely frosted.

Possible causes

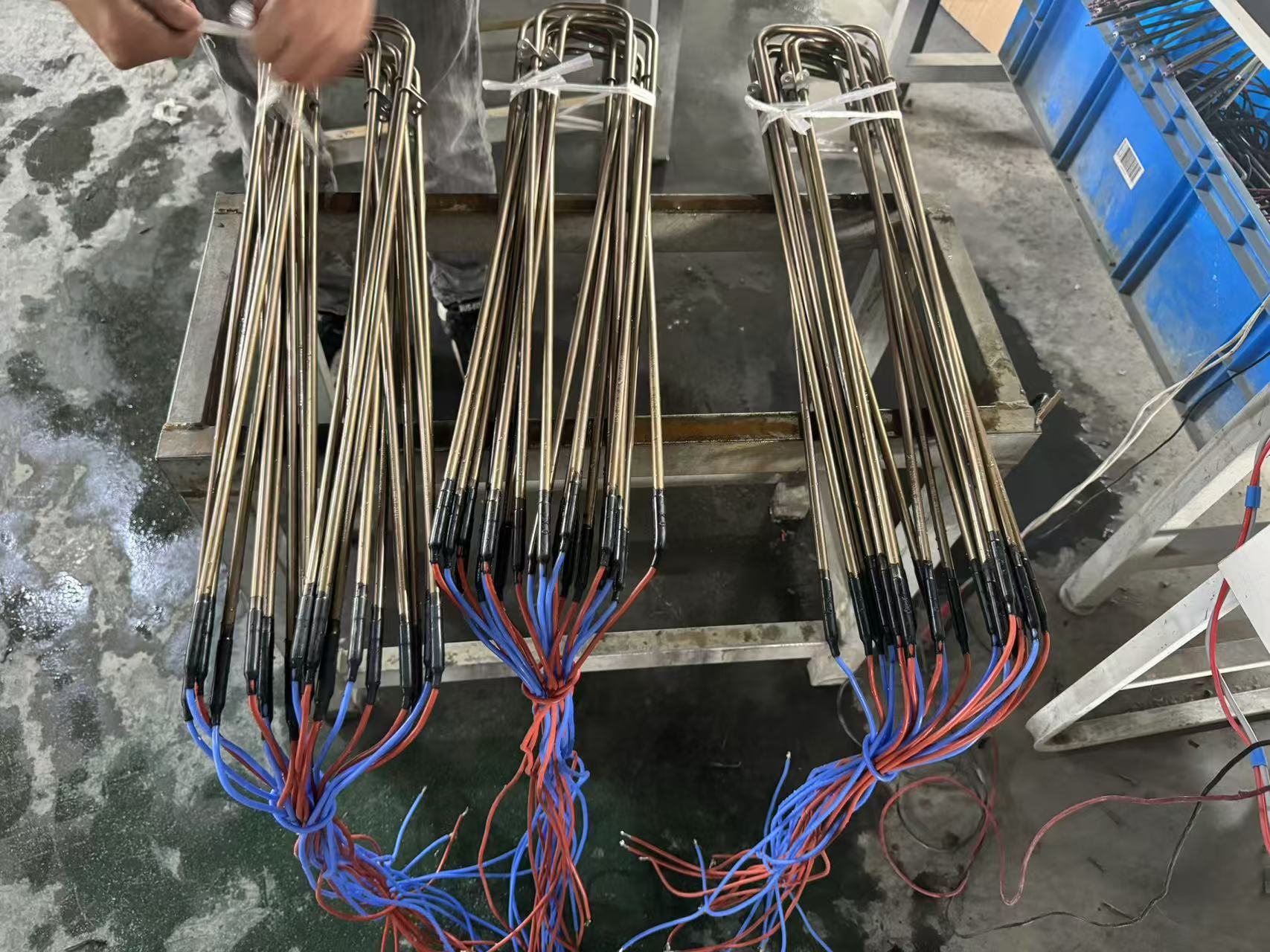

1. The heating wire inside the defrost heater tube in refrigerators/freezer/unit cooler has burned out, or the connection terminals are loose or fallen off.

2. The defrost sensor is malfunctioning and cannot send the start signal.

3. The defrost relay is faulty, and the circuit cannot conduct.

Troubleshooting method

1. After power off, use a multimeter to measure the resistance value at both ends of the defrost heater tube. If the resistance value is infinite, it indicates that the heating wire has burned out, and the defrost heating tube of refrigerator/freezer/unit cooler needs to be replaced.

2. Check if the connection terminals are loose, and re-tighten them; if the terminals are oxidized, clean the oxide layer before connecting.

3. Test the on-off state of the defrost sensor and relay. If there is an abnormality, replace the corresponding components.

Fault 2: The defrosting is not thorough, and there is still residual frost in some areas.

Possible causes

1. The power of the defrost heating element does not match the equipment’s rated power, resulting in insufficient heat generation.

2. The installation position of the defrost heating tube is offset, and it does not fit tightly with the evaporator.

3. The defrosting time setting is too short, and the heat is not fully transferred.

Troubleshooting method

1. Check the power parameters of the defrost heater heating tube and replace it with a product that matches the equipment’s rated power.

2. Adjust the installation position of the defrosting heating tube to ensure it is in close contact with the frost-covered area of the evaporator.

3. Contact the equipment manufacturer or maintenance personnel to reset the defrost program’s running time.

Fault 3: The defrost heating tube heats up normally, but there is water leakage / freezing.

Possible causes

1. The water drainage channel is blocked, and the melted frost water cannot be discharged normally.

2. The defrosting heating pipe stops running after defrosting but not in time, causing the evaporator temperature to be too high and resulting in water overflow.

3. The drainage hole of the equipment’s inner tank is blocked.

Troubleshooting method

1. Clean the debris and ice in the drainage channel below the evaporator and the drainage holes to ensure smooth drainage.

2. Test the temperature control accuracy of the defrost sensor. If the stop temperature is too high, calibrate or replace the sensor.

3. After defrosting, promptly clean the water accumulation in the water collection tray to prevent it from freezing again.

Fault 4: The surface of the heating tube is rusted or leaks.

Possible causes

1. The selected stainless steel material has insufficient corrosion resistance (such as not 304/316 material).

2. The internal humidity of the equipment is abnormally high, or there is acidic / alkaline condensate water that corrodes.

3. The coating on the surface of the heating tube is damaged, losing its protective effect.

Troubleshooting method

1. Replace the defrosr heating tube with one made of stainless steel 304/316 material to enhance corrosion resistance.

2. Check if the equipment door seal is tightly sealed to reduce the entry of humid air from the outside.

3. If the defrost heating tube leaks, immediately stop the machine and replace it to avoid short-circuit faults.

Media Contact

Company Name: Shengzhou Jinwei Electric Heating Appliance Co., Ltd.

Email:Send Email

Country: China

Website: https://www.jingweiheat.com/