High frequency pipe making machine , which is called tube mill, is a crucial part of industrial equipment intended to make steel pipes from steel coils. These machines are widely used in industries, including construction, oil and gas, automotive, furniture, energy, and infrastructure.

With manufacturing technology developing faster and faster, high frequency steel tube mill is becoming more and more automated, efficient , which to the largest extent help factory cost down and improve product quality.

What Is a Pipe Making Machine?

High frequency steel tube mills are designed to make round, square and rectangle pipes by a series of process such as forming, welding and sizing. ERW pipe making machine( Electric Resistance Welding) uses high-frequency current to heat and weld the edges of the steel strip.

Main Components of a Pipe Making Machine

The standard pipe making machines are as follows:

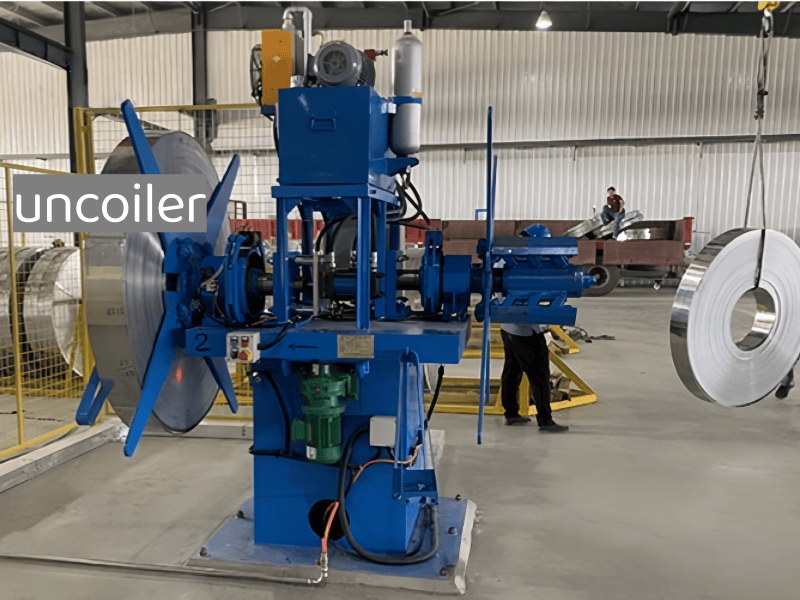

Uncoiler – Feeds the steel coil into the line.

Shear & Butt Welder – Connects strip ends for continuous production.

Accumulator (Cage or Spiral type) – Stores strip to avoid line stoppage.

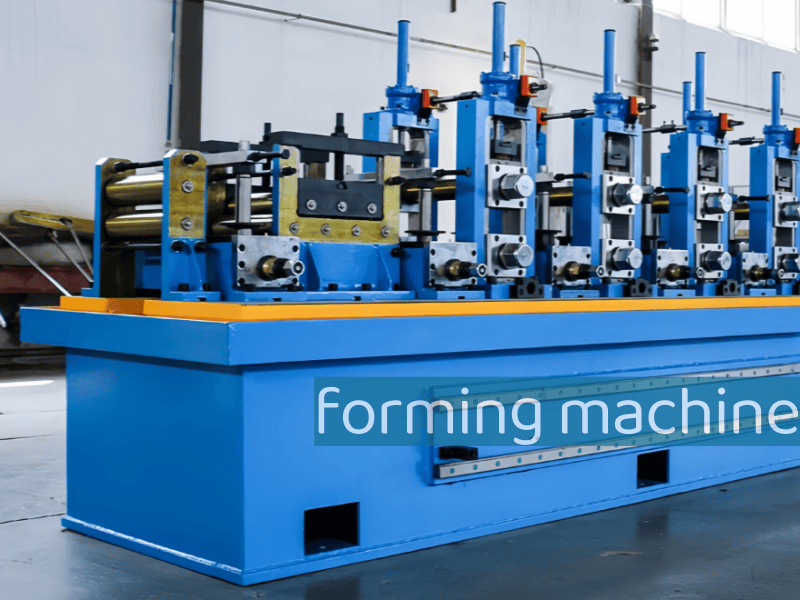

Forming Section – Gradually shapes the strip into a round tube.

High-Frequency Welder – Welds the tube seam.

Sizing Section – Adjusts diameter and shape accuracy.

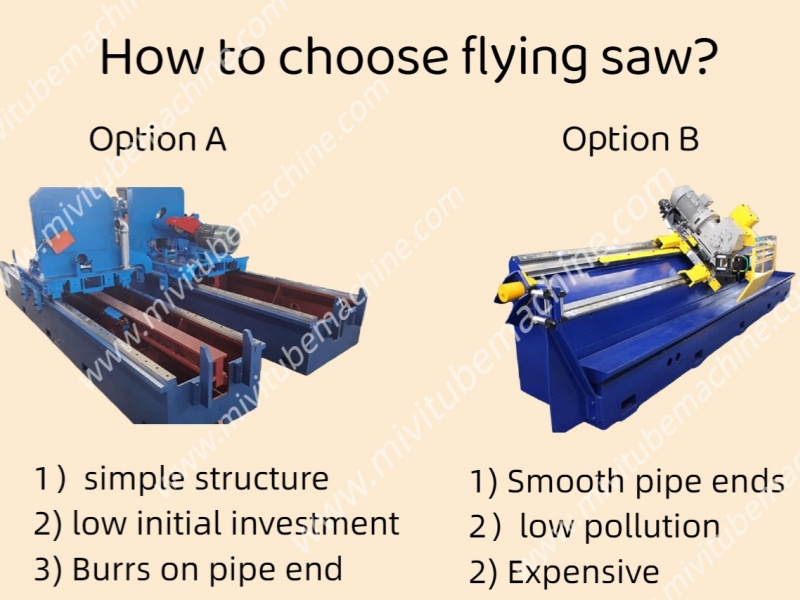

Flying Saw / Cold Saw – Cuts pipes to fixed length.

Run-out Table & Stacker – Collects finished pipes.

Working Process of a Pipe Making MachineThe basic working process includes:The work flow includes:Steel coil → Uncoiling → Forming → Welding → Cooling → Sizing → Cutting → Stacking

During the welding stage, high-frequency current flows through the tube edges, generating heat. Pressure rollers squeeze the edges together, forming a strong and continuous weld.

Key Advantages of Modern Pipe Making Machines

Modern tube mills offer many advantages:

High production efficiency

Stable welding quality

Low material waste

High automation with PLC control

Easy size changeover

Compatible with Industry 4.0 systems

These features make pipe making machines ideal for both large factories and new investors.

Applications of Pipes Produced

Pipes manufactured by tube mills are used in:

Building structures and scaffolding

Water and gas pipelines

Automotive parts

Furniture and fitness equipment

Solar panel supports

Agricultural irrigation systems

How to Choose the Right Pipe Making Machine

When selecting a pipe making machine, consider:

Pipe diameter range

Wall thickness

Material type (carbon steel, GI, stainless)

Production speed

Power supply standards

After-sales service and spare parts

Choosing the right supplier with strong technical support is just as important as the machine itself.

Future Trends in Pipe Making Technology

The future of pipe making machines focuses on:

Energy-saving welding systems

Digital quality monitoring

Remote diagnostics and maintenance

These trends help manufacturers improve competitiveness and reduce long-term operating costs.

Conclusion

High frequency pipe making machine is the key equipment of any modern tube production plant. With the right configuration and reliable supplier, it can bring long-term value through stable output, high quality, and excellent return on investment.

For companies entering the steel pipe industry, investing in a high-quality pipe making machine is the first and most critical step toward success.

Media Contact

Company Name: Yangzhou Mivi Machinery Manufacturing Co., Ltd.

Email:Send Email

Country: China

Website: https://www.mivitubemachine.com/