Pneumatic butterfly valves are an indispensable component in modern industrial fluid control systems and are one of the most versatile and cost-effective solutions. They are used in industries ranging from chemical processing to water treatment and oil and gas. This article discusses in detail the working principle, key advantages, technical features, and application scenarios of pneumatic butterfly valves.

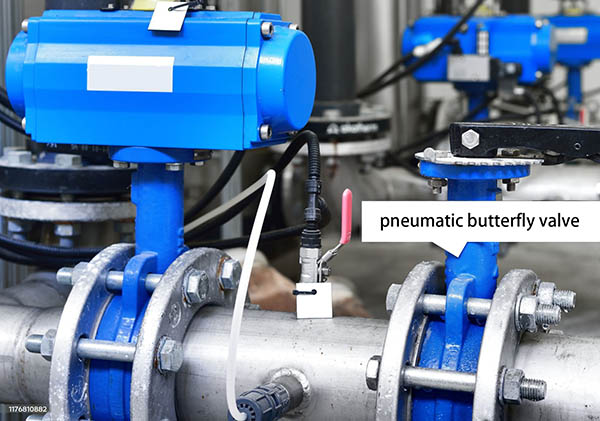

1. What is a pneumatic butterfly valve?

A pneumatic butterfly valve is a combination of a butterfly valve and a pneumatic actuator, using compressed air to control valve operation. Its core is a disc-shaped disc that rotates within the pipeline to regulate or isolate the flow of liquid or gas. Its simple design, fast operation, and economical performance make it a preferred alternative to ball valves or gate valves, especially in large-diameter pipelines.

2. Working Principle of Pneumatic Butterfly ValvePlay

Pneumatic butterfly valves use compressed air to rotate the valve stem, which in turn rotates the disc 90° around its axis, thereby controlling the flow of fluid. The valve's initial position (open or closed) is set according to actual needs. Here's how it works: Compressed air enters the pneumatic actuator, pushing the piston or diaphragm to rotate the valve stem, which in turn rotates the disc.

2.1 Single-Acting vs. Double-Acting:

- Single-Acting: Air is used to open or close the valve. A built-in spring returns the valve to its original position (normally open or closed) upon loss of air pressure. This spring-return feature automatically closes or opens the valve in the event of an air or power outage, making it suitable for hazardous environments and providing enhanced safety.- Double-Acting: Air pressure is required to control both the opening and closing of the valve, providing precise control but without an automatic reset feature.

2.2 Speed and Reliability:

Pneumatic actuators offer fast response times (up to 0.05 seconds per cycle), ensuring rapid opening and closing of butterfly valves, reducing downtime and preventing wear caused by sticking. Pneumatic butterfly valves offer the fastest opening and closing speeds of all butterfly valve actuators.This quarter-turn rotation mechanism, combined with precise actuator control, makes pneumatic butterfly valves ideal for automated systems requiring fast and reliable operation.

3. Key Advantages of Pneumatic Butterfly Valves

3.1. Simple and Compact Structure:

Compared to ball or gate valves, butterfly valves occupy less space and require less structural support, making them suitable for small, medium, and large-diameter pipelines.

3.2. Cost-Effective:

Fewer components and lower material usage result in a significantly lower initial cost than other valve types of the same caliber.

3.3. Fast Operation:

Pneumatic actuators enable rapid opening and closing, improving system efficiency and responsiveness, especially in emergency situations.

3.4. Low Maintenance:

Simple design and durable materials reduce maintenance requirements, lowering downtime and operating costs.

3.5. Low Pressure Drop:

When the valve is fully open, the disc aligns with the flow direction, reducing resistance, lowering pressure loss, and improving energy efficiency.

4. Applications of Pneumatic Butterfly Valves

- Water and Wastewater Treatment: Controlling water flow and liquid level is the most basic application of butterfly valves.- Chemical Industry: Used to regulate corrosive fluids, equipped with PTFE or stainless steel components for increased durability. - Oil & Gas: Eccentric pneumatic butterfly valves are suitable for high-pressure, high-temperature fluid pipelines.- HVAC systems: They regulate air or water flow, maintain temperature and humidity, and improve energy efficiency.- Food & Beverage: Hygienic designs using stainless steel or WRAS-certified components meet stringent hygiene standards.- Power Plants: Single-acting actuators ensure safe shutoff in high-risk environments, improving operational safety.- Mining & Paper: Robust, corrosion-resistant valves are used to handle slurry or pulp flows.

5. Why Choose ZFA Pneumatic Butterfly Valves?

With nearly 20 years of experience in butterfly valve manufacturing, ZFA is committed to providing high-performance, precise, and efficient pneumatic butterfly valves.

The following are ZFA's unique advantages:- Customized Solutions: We offer a variety of materials, actuator types, and connection methods to meet specific application requirements.- Strict Quality Control: Each valve undergoes rigorous testing to ensure reliability.- Global Trust: Our products are exported to South Africa, the Middle East, Europe, Southeast Asia, South America, and other countries, earning a deep customer trust. - Professional Support: Our team provides rapid response (within 24 hours) and technical guidance to help you select the optimal valve.

6. Conclusion

Pneumatic butterfly valves, with their simple design, fast operation, and cost-effectiveness, have become an indispensable component of modern piping systems. Their versatility across multiple industries and customizable designs make them an ideal choice. ZFA Valves is committed to providing high-performance pneumatic butterfly valves that meet stringent safety and performance standards, improving your operational efficiency.

Media Contact

Company Name: Tianjin Zhongfa Valve Co., Ltd.

Email:Send Email

Phone: +86 13212024235

Address:No.38, Baoyuan Road, Jinnan Economic Development Zone, Jinnan District

City: Tianjin

Country: China

Website: https://www.zfavalve.com/