Industrial paper serves as a cornerstone in manufacturing and packaging industries. It includes materials like Kraft paper, corrugated cardboard, coated paper, duplex cardboard, and specialty papers. Each type offers unique properties tailored for specific applications, such as packaging, printing, and consumer goods, ensuring efficiency and durability in industrial processes.

Key Takeaways

- Kraft paper is highly durable and eco-friendly, making it ideal for heavy-duty packaging and aligning with sustainability trends in the industry.

- Corrugated cardboard’s unique structure provides excellent cushioning and strength, making it essential for safe shipping and packaging across various sectors.

- Coated paper enhances print quality with its smooth surface, making it perfect for high-end marketing materials and publications.

Kraft Paper in Industrial Paper

Characteristics

Kraft paper stands out for its exceptional strength and durability. Its high tear resistance makes it suitable for demanding industrial applications. The paper’s natural brown color results from minimal chemical processing, which also enhances its eco-friendly appeal. Manufacturers often produce Kraft paper in varying thicknesses to meet specific requirements. Its biodegradable nature aligns with the growing demand for sustainable materials in the industrial paper sector.

Production Process

The production of Kraft paper involves the chemical pulping process, also known as the Kraft process. This method uses a mixture of sodium hydroxide and sodium sulfide to break down wood chips into cellulose fibers. The process removes lignin, a component that weakens paper, while retaining the cellulose, which provides strength. After pulping, the fibers are washed, screened, and pressed into sheets. The final product undergoes drying and rolling before being distributed for industrial use.

Common Applications

Kraft paper plays a vital role in various industries. It is widely used for packaging, including paper bags, wrapping materials, and corrugated boxes. Its strength makes it ideal for heavy-duty sacks used in construction and agriculture. Additionally, it serves as a base material for laminates and coated papers. The versatility of Kraft paper ensures its continued relevance in the industrial paper market.

Corrugated Cardboard in Industrial Paper

Structure and Types

Corrugated cardboard consists of three main layers: an outer liner, an inner liner, and a fluted corrugated medium sandwiched between them. This structure provides exceptional strength and cushioning, making it ideal for packaging. The fluted layer acts as a shock absorber, protecting contents from damage during transportation. Corrugated cardboard comes in various types, including single-wall, double-wall, and triple-wall. Single-wall cardboard is lightweight and suitable for everyday packaging needs. Double-wall and triple-wall options offer enhanced durability and are used for heavy-duty applications. The versatility of corrugated cardboard allows manufacturers to customize its thickness and flute size based on specific requirements.

Manufacturing Process

The production of corrugated cardboard begins with the creation of the fluted medium. A corrugator machine heats and presses paper into a wavy pattern. Adhesive is then applied to the peaks of the flutes, and the medium is bonded to the outer and inner liners. The process continues with cutting, scoring, and folding the cardboard into desired shapes and sizes. Advanced machinery ensures precision and efficiency, enabling large-scale production. Manufacturers often use recycled materials in the process, contributing to the sustainability of this industrial paper product.

Uses in Packaging

Corrugated cardboard is a cornerstone of the packaging industry. Its lightweight yet sturdy design makes it ideal for shipping boxes, retail displays, and protective packaging. Industries such as e-commerce, food, and electronics rely heavily on corrugated cardboard for safe product delivery. Its recyclability and cost-effectiveness further enhance its appeal. Custom printing options allow businesses to use corrugated cardboard for branding and marketing purposes, adding value beyond its functional role.

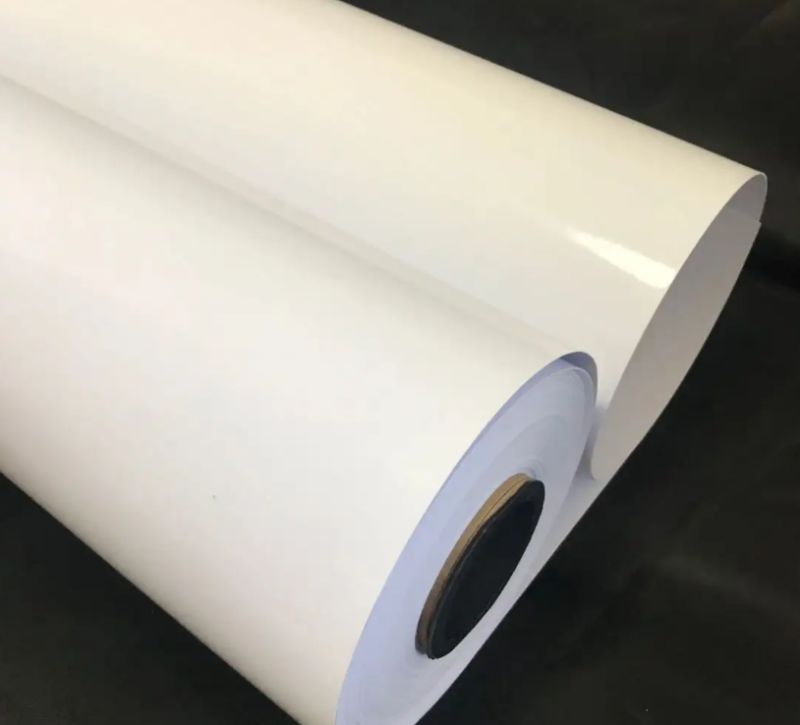

Coated Paper in Industrial PaperFeatures

Coated paper offers a smooth and polished surface, enhancing its visual appeal and functionality. Manufacturers apply a coating layer to the base paper, which improves brightness, opacity, and ink absorption. This process results in sharper image reproduction and vibrant colors, making it ideal for high-quality printing. Coated paper also resists dirt and moisture, ensuring durability. Its availability in various finishes, such as matte, gloss, and satin, provides versatility for different industrial needs.

Types of Coatings

Coated paper features two primary types of coatings: single-sided and double-sided. Single-sided coatings are applied to one side of the paper, often used for packaging and labels. Double-sided coatings cover both sides, making them suitable for brochures and magazines. Coating materials include clay, calcium carbonate, and polymers. These materials enhance the paper’s smoothness and printing capabilities. Some coatings also add specific properties, such as water resistance or greaseproofing, to meet specialized requirements.

Applications in Printing

Coated paper plays a significant role in the printing industry. Its smooth surface ensures precise ink application, producing sharp text and vivid images. Industries use it for creating marketing materials, including flyers, catalogs, and posters. High-end publications, such as art books and photography magazines, rely on coated paper for superior image quality. Its adaptability to various printing techniques, such as offset and digital printing, further solidifies its importance in industrial paper applications.

Duplex Cardboard in Industrial PaperProperties

Duplex cardboard is a versatile material known for its durability and smooth surface. It features a white-coated side for printing and a gray back for structural support. This combination provides excellent stiffness and break resistance, making it suitable for packaging applications. Its high whiteness and smoothness enhance print quality, ensuring vibrant and sharp designs. Duplex cardboard also offers moisture resistance, which protects packaged goods from environmental factors. Manufacturers produce it in various thicknesses to meet diverse industrial needs, ensuring adaptability across multiple sectors.

Manufacturing Process

The production of duplex cardboard begins with recycled paper pulp. Manufacturers layer the pulp to create a sturdy base, followed by a coating process on one side. This coating, typically made from clay or other materials, enhances the surface’s smoothness and printability. The cardboard undergoes pressing and drying to achieve the desired thickness and strength. Advanced machinery ensures uniformity and precision throughout the process. Quality control measures verify that the final product meets industry standards for packaging and printing applications.

Uses in Consumer Goods

Duplex cardboard plays a crucial role in the packaging of consumer goods. Industries use it for creating cartons for household appliances, electronics, and toys. Its ability to support high-quality printing makes it ideal for gift boxes and branded packaging. The food industry often relies on duplex cardboard for indirect food packaging, such as cereal boxes and snack containers. Its cost-effectiveness and recyclability further enhance its appeal, aligning with the growing demand for sustainable packaging solutions.

Specialty Papers in Industrial PaperOverview

Specialty papers represent a unique segment within the industrial paper sector. These papers are designed to meet specific functional requirements that standard paper types cannot fulfill. Their production often involves advanced treatments or coatings to achieve specialized properties such as heat resistance, water repellence, or enhanced durability. Specialty papers cater to niche markets, offering tailored solutions for industries requiring precision and reliability. Their adaptability and performance make them indispensable in various industrial applications.

Examples

Specialty papers encompass a wide range of products, each serving distinct purposes. Thermal paper, for instance, is widely used in point-of-sale systems and receipt printing due to its heat-sensitive coating. Greaseproof paper, another example, finds extensive use in the food industry for wrapping oily or greasy products. Other notable types include filter paper for industrial filtration, release paper for adhesive products, and security paper for documents requiring anti-counterfeiting measures. Each type of specialty paper is engineered to deliver optimal performance in its respective application.

Niche Applications

Industries rely on specialty papers for tasks requiring precision and specialized properties. The medical field uses sterilization paper for packaging surgical instruments, ensuring hygiene and safety. The automotive sector employs abrasive paper for surface finishing and polishing. Specialty papers also play a critical role in the electronics industry, where they serve as insulation materials or protective layers. Their ability to address specific challenges underscores their importance in the broader industrial paper landscape.

Industrial paper plays a vital role in packaging, printing, and specialty applications. Each type, from Kraft paper to specialty papers, offers unique properties tailored to specific industrial needs. Selecting the right type ensures efficiency and sustainability. Businesses should evaluate their requirements carefully to leverage the full potential of industrial paper in their operations.

FAQWhat is the most sustainable type of industrial paper?

Kraft paper is the most sustainable option. Its biodegradable nature and minimal chemical processing make it eco-friendly, aligning with the growing demand for environmentally responsible materials.

How does duplex cardboard differ from other industrial papers?

Duplex cardboard features a white-coated side for printing and a gray back for structural support. This combination ensures durability, moisture resistance, and high-quality printability for packaging applications.

Can specialty papers be recycled?

Recyclability depends on the type of specialty paper. Papers with minimal coatings or treatments, like greaseproof paper, are often recyclable, while heavily treated ones may require specialized recycling processes.

Media Contact

Company Name: Ningbo Tianying Paper Co., LTD.

Email:Send Email

Country: China

Website: https://www.bincheng-paper.com/