What is a Vortex Flow Meter?

A vortex flow meter is a device installed in a system of flow processing for detecting the vortices generated as fluid passes a bluff body. It's widely used in gas, liquid and steam processing for flow measurement to improve production efficiency and allocation.

Vortex Flow Meter Working Principle

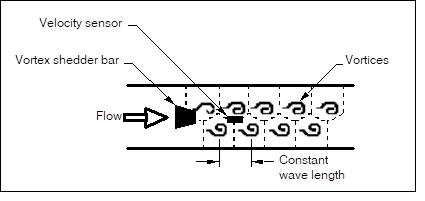

Vortices are alternately shed from each side of the bluff body when fluids passing through a non-streamlined object. Pressure variations generated in the process of are directly proportional to the flow velocity. Frequency of vortex shedding are detected to calculate the flow rate. Then the frequency will be translated into a signal that provides a precise measurement of volumetric or mass flow for liquids, gases, and steam.

Structural Design of Vortex Flow Meters

316 Stainless steel or Hastelloy is the primary material made of a flow meter in typical, including a bluff body, an assembled vortex sensor and transmitter electronics. A vortex shedding flow meter is available in flange sizes from ½ in. to 12 in. Moreover, the installation cost of a vortex shedding meter is competitive than that of orifice meters in size under six inches.

Dimensions and bluff body shapes like square and rectangular have gone through experiments to reach desired effects. Experimental results indicate that linearity and sensitivity to velocity profile are slightly different with bluff body shape. The bluff body should contain a large enough fraction of the pipe diameter. Then the entire flow participate in the shedding. In despite of the flow rate, protruding edges on the upstream face are indispensable special designs to allocate lines of flow separation.

At present, the majority of vortex meters integrates piezoelectric or capacitance-type sensors to measure the pressure oscillation near the bluff body. These sensors output a low voltage signal as a responding to the pressure oscillation. Such signals have the same frequency as the oscillation. Those modular and inexpensive sensors could be replaced easily and adaptable over a wide temperature range from cryogenic liquids to superheated steam.

Why Choose Vortex Flow Meters?

No moving parts ensure durability, low maintenance and long-term reliability in a processing system. Such flow meters also stand out in measuring a diverse array of fluids accurately, even across wide-ranging temperatures and pressures. Precisely because of multifunctionality as well as outstanding performances in precision and repeatable measurements, they are go-to solutions for industries valuing accuracy. Reduced operating costs and easy installation are two more reasons as the go-to solution.

Request a Free Quote

Accuracy and Rangeability

The rangeability of vortex flowmeters decreases as the viscosity increases for falling off Reynolds number with viscosity going up. The maximum viscosity ceilling lies within 8 ~ 30 centipoises. In the event that the vortex meter is sized properly for the application, one could anticipate a better rangeability than 20:1 for gas and steam, and over 10:1 for low-viscosity fluids.

The inaccuracy of vortex flow meters vary with Reynolds numbers. Such inaccuracy of most vortex flowmeters rests between 0.5% and 1% while it goes up to 10% when Reynolds number smaller than 10,000. A vortex meter features a cut-off point for indications at near zero flows. Meter outputs are clamped at zero when Reynolds numbers at or below 10,000. There are no problems in case the minimum flow waiting for measurement is two times of the cut-off point. Low flow rates could not be measured accurately in the process of start-up, shutdown and other upset conditions for their rangeability.

Maximize Efficiency and Reduce Costs

Operators are able to adjust and optimize flow of liquids, gases or steam sending through the processing system relying on accurate flow measurement. So that the allocation efficiency is improved while the energy consumption is lowered. All in all, integrating these flow meters into automation systems are helpful for ongoing improvements in operational performance, reducing downtime and enhancing overall productivity.

Limitations of Vortex Flowmeter

Vortex meters are generally not ideal for batching or intermittent flow processes due to their performance limitations at low flow rates. Specifically, the dribble flow rate of batching stations may fall below the vortex meter’s minimum Reynolds number threshold, leading to inaccuracies. As the total batch size decreases, the likelihood of measurement errors increases, making the meter less reliable for these applications. It's important to select a flow meter that can handle the specific flow profile required for such operations to avoid significant errors.

Our expert team is ready to offer tailored solutions that meet the specific needs of your industry, whether it’s oil and gas, chemical processing, or HVAC systems. With a commitment to quality and performance, we provide comprehensive support to ensure you choose the right vortex flow meter for your application. Contact us today for a personalized consultation and see how our flow meters can revolutionize your process control and efficiency.

Media Contact

Company Name: SHENZHEN LONNMETER GROUP

Email:Send Email

Country: China

Website: https://www.lonnmeter.com/