In modern production management, warehousing systems are an indispensable part. Reasonable warehouse management can provide enterprises with more accurate inventory management and data analysis functions, help them better grasp market demand and resource conditions, and achieve goals such as optimizing production plans, reducing inventory risks, and improving supply chain controllability and flexibility. With the continuous development and application of artificial intelligence, Big data and other technologies, intelligent storage has gradually become the inevitable trend of future development.

VICTORY GIANT Technology (Huizhou) Co., Ltd. (hereinafter referred to as “Victory Giant Technology”) was established in 2006 and successfully listed on the Shenzhen Stock Exchange ChiNext in 2015. It focuses on the research and development, production, and sales of high-precision circuit boards and HDI PCBs. Its products are widely used in computer, aerospace, automotive electronics, 5G New Infrastructure, Big data center, industrial interconnection, medical instruments and other fields. Victory Giant Technology is a vice chairman unit of CPCA and one of the industry standard setting units. It ranks 25th on the global PCB supplier list (Prismark) and 4th on the domestic investment list of China’s top 100 printed circuit industry enterprises. It has established long-term and stable cooperative relationships with more than 160 top enterprises worldwide.

With the continuous expansion of enterprise scale and the gradual enrichment of product lines, Victory Giant Technology’s demand for storage has become increasingly urgent. How to improve storage and management efficiency has become a key issue that needs to be addressed in its development process. Therefore, Victory Giant Technology has chosen to cooperate with Fande Automation to establish an automated warehouse in Huizhou, with ROBOTECH as the supplier of core equipment for the finished product warehouse.

1. Customized storage solutions to meet diverse needs

- Three storage areas - Fixed width storage area 1 & fixed width storage area 2 & variable width storage area - 11 sets of Cheetah track tunnel stacker crane systems - 10 dual depth models & 1 single depth model - Only 3-5 months

ROBOTECH has comprehensively considered the storage needs and pain points of Victory Giant Technology and provided customized solutions for it. In this process, multiple technologies were innovatively integrated, making the overall solution more efficient and intelligent.

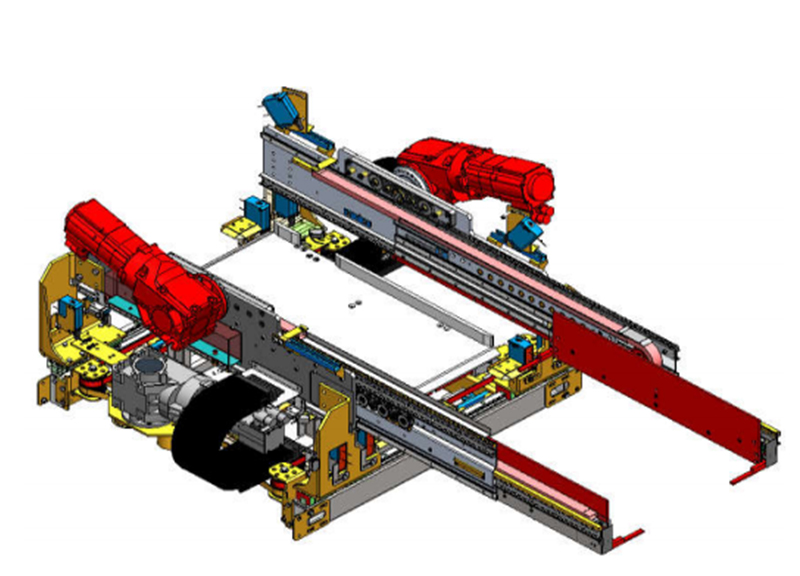

The automated warehouse is planned with three storage areas: fixed width storage area 1, fixed width storage area 2, and variable width storage area, which can meet the storage needs of different goods. ROBOTECH has equipped it with 11 sets of Cheetah track tunnel stacker crane systems, including 10 dual depth models and 1 single depth model. The Cheetah stacker crane is a lightweight, high-strength, low-density alloy material material box model that has low requirements for ground load-bearing and can significantly reduce energy consumption. At the same time, it can shorten the project implementation cycle and can be put into use in only 3-5 months.

The stacker crane system adopts dual servo motor drive to provide ample power. In addition, the clamping wheel method on both sides is used to provide strong friction by tightening the ground rail. The lifting part adopts synchronous belt drive technology, ensuring stable operation while also achieving horizontal and lifting speeds of up to 240m/min and 120m/min, respectively, and acceleration of up to 2m/s², This greatly meets the high demand of the warehouse for large flow, large number of cargo spaces, and complex cargo rules, as well as high requirements for the level, lifting speed, and acceleration of the stacker crane, providing it with efficient storage and warehousing capabilities. Compared to traditional warehousing modes, the efficiency is improved by at least 200%.

It is worth mentioning that for automated warehouse storage of box type goods, if they need to be stored independently on shelves, bracket type shelves are usually used, but the cost is relatively high. If it is corrugated cardboard boxes, they may experience bottom deformation and even fall off the shelves due to insufficient strength. For this reason, ROBOTECH innovatively uses a gripping telescopic fork, which can store boxes on crossbeam shelves. Two fork arms are extended from both sides of the box, and mechanical fingers are rotated to push or pull the box back. This type of telescopic fork can handle boxes with a minimum size of 200mm * 300mm and a maximum box length of over 1000mm. It can store boxes of the same size or different sizes in the same tunnel, making it flexible and versatile, significantly save storage space and shelf manufacturing costs.

▲ Schematic diagram of clamping telescopic fork

2. Intelligent warehousing drives the transformation and upgrading of intelligent manufacturingThe completion of this project demonstrates the trend of modern manufacturing development. With the continuous innovation and application of technology, the traditional manufacturing industry is transforming and upgrading towards intelligent manufacturing with the goal of improving efficiency, reducing costs, and improving quality. As a promoter of intelligent manufacturing and a practitioner of Industry 4.0, ROBOTECH has a wide customer base and rich case experience worldwide, and has become a globally renowned provider of automated warehousing solutions. Through in-depth understanding of customer needs and an accurate grasp of Market trend, ROBOTECH has always been committed to providing customers with more efficient, intelligent and sustainable automated warehousing solutions to help manufacturing enterprises achieve intelligent transformation

Media Contact

Company Name: NANJING INFORM STORAGE EQUIPMENT (GROUP) CO., LTD

Email:Send Email

Phone: +86 13851666948

Country: China

Website: https://www.inform-international.com/