Anebon will use advanced equipment and experienced team to customize the products people imagine, and Anebon believe that it can meet people's needs both in terms of price and quality.

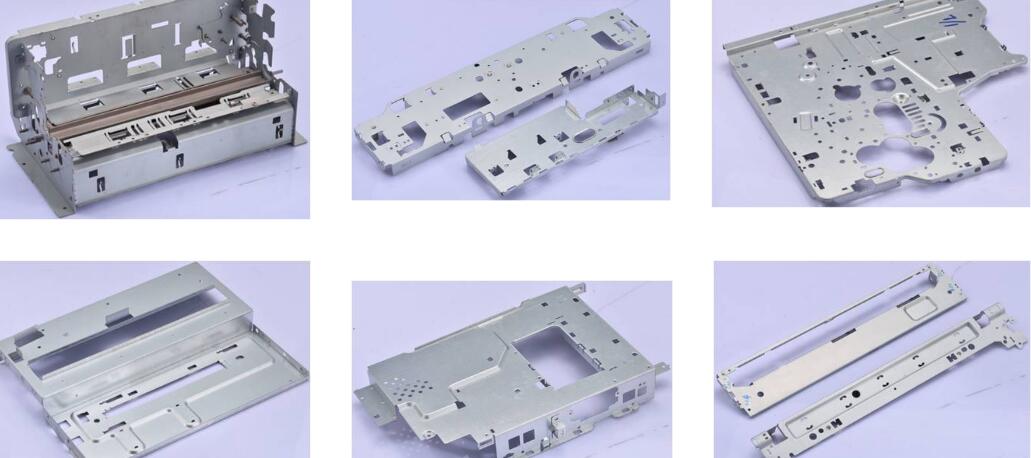

The metal sheet is formed into various sheet-like parts and shells, container-like workpieces on a press by a mold, or the tube pieces are made into various tubular workpieces. This type of forming process in the cold state is called cold stamping, referred to as stamping.

Stamping processing is the production technology of product parts with certain shape, size and performance by means of the power of conventional or special stamping equipment, which directly deforms and deforms the sheet in the mold. Sheets, molds and equipment are the three elements of stamping.

The main process types: punching, bending, shearing, drawing, bulging, spinning, correction.

Applications: Aviation, military, machinery, agricultural machinery, electronics, information, railways, post and telecommunications, transportation, chemicals, medical equipment, household appliances and light industry.

Anebon use precision molds, the precision of the workpiece can reach micron level, and the repeating precision is high, the specifications are the same, and the holes and the bosses can be punched out.

(1) Anebon's stamping process is highly efficient, easy to operate, and easy to mechanize and automate. The number of strokes of a common press is up to several tens of times per minute, and the high-speed pressure can be hundreds or even thousands of times per minute, and a punch can be obtained for each press stroke.

(2) Since the die guarantees the size and shape accuracy of the stamping part during stamping, and generally does not damage the surface quality of the stamping part, and the life of the die is generally long, the quality of the stamping is stable, the interchangeability is good, and it has “the same” characteristics.

As a complete tool and die shop, Anebon skilled in all areas of fabrication including fiber laser, CNC punching, CNC bending, CNC forming, welding, CNC machining, hardware insertion and assembly.

Anebon accepts raw material in sheets, plates, bars or tubes and are experienced in working with a variety of materials like aluminum, copper, stainless steel and carbon steels. Other services include hardware insertion, welding, grinding, machining, turning and assembly. As people's volumes increase Anebon also have the option of hard tooling their parts to run in Anebon metal stamping department. Inspection options range from simple feature checks all the way through FAIR & PPAP.

Media Contact

Company Name: Anebon Metal Products Co., LTD.

Contact Person: Media Relations

Email:Send Email

Phone: +86-13509836707

Country: China

Website: https://www.anebonmetal.com/