Choosing the right CNC Drilling and Milling Machine is paramount. Factories align machine selection with operational needs, material requirements, and budget for optimal production. This reflects “Why More Factories Are Choosing High-Precision CNC Drilling and Milling Machines.” A trusted CNC Machine Manufacturer helps evaluate the “5 Critical Factors to Consider When Buying a CNC Drilling and Milling Machine,” crucial for Automotive Parts Machining, even when considering a CNC Lathe.

Key Takeaways

- Understand your factory’s needs, like production volume, materials, and part complexity, before choosing a CNC machine.

- Evaluate machine features such as vertical or horizontal design, number of axes, spindle power, and software integration to match your production goals.

- Consider the total cost, including purchase price, operating expenses, and manufacturer support, to ensure a good return on your investment.

Defining Your Factory’s Production Needs and Material Demands

Selecting the ideal CNC drilling and milling machine begins with a thorough understanding of a factory’s specific production needs and the characteristics of the materials it processes. This foundational step ensures the chosen machine aligns perfectly with operational goals.

Production Volume and Throughput Expectations

A factory’s production volume directly influences the type and number of CNC machines it requires. High-volume production demands machines capable of continuous operation and rapid cycle times. Conversely, lower volumes might allow for more versatile, less specialized equipment. For instance, one-off production, also known as low-volume production, typically involves manufacturing between 1 and 100 units per year. Factories producing such quantities often prioritize flexibility and quick changeovers over sheer speed. Understanding these throughput expectations helps determine if a factory needs a single, highly automated machine or multiple, simpler units.

Types of Materials and Their Hardness

The materials a factory processes significantly impact machine selection, particularly concerning spindle power, tooling, and machine rigidity. Different materials possess varying hardness and machinability ratings.

| Material | Brinell Hardness (HB) |

|---|---|

| Titanium Grade 5 | 334 |

| Stainless Steel 316 | 149 |

| Aluminum 6061 | 95 |

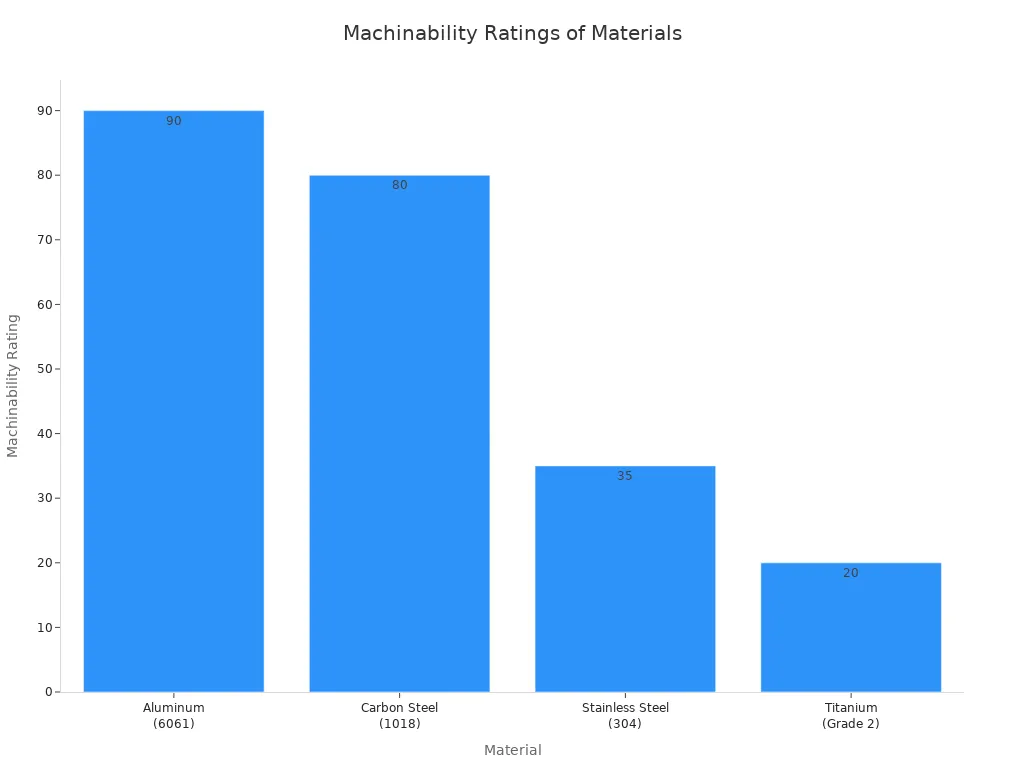

Machinability ratings provide a clearer picture of how easily a material cuts.

| Material | Machinability Rating | Comments |

|---|---|---|

| Aluminum (6061) | 90 | Good machinability, soft and easy to machine. |

| Carbon Steel (1018) | 80 | Fairly easy to machine, common in industrial applications. |

| Stainless Steel (304) | 35 | Poor machinability due to toughness and work hardening. |

| Titanium (Grade 2) | 20 | Low machinability, prone to heat buildup and tool wear. |

Hardened and tempered steels typically have hardnesses ranging from >45-68 HRC. Examples include carburizing steel (~60 HRC), ball bearing steel (~60 HRC), and tool steel (~68 HRC). Processing these harder materials requires machines with higher rigidity, greater spindle power, and specialized tooling.

| Material Type | Key Material Properties | Recommended Tooling / Considerations |

|---|---|---|

| Metals | ||

| Aluminum | Machinability, efficient chip evacuation | High-helix carbide end mills |

| Stainless Steel | Hardness, heat resistance | Tough, heat-resistant coatings (e.g., TiAlN) |

| Titanium | Hardness, tool wear prevention | Rigid tooling, sharp geometry, slower cutting speeds |

| Brass and Copper | Soft, easy to cut | Sharp uncoated carbide tools |

| Plastics | ||

| ABS, POM, Acrylic | Low melting point, deformation risk | Sharp tools, low cutting temperatures, single-flute end mills for chip evacuation |

| Composites | ||

| Carbon Fiber (CFRP), Fiberglass (GFRP) | Delamination, edge fraying | Diamond-coated tools, specialized compression cutters for clean edges |

Understanding these material properties helps a factory choose the correct machine and tooling for efficient and high-quality production.

Part Size, Complexity, and Required Precision

The physical characteristics of the parts a factory produces significantly influence machine selection. This includes their size, geometric complexity, and the precision they demand.

Part complexity, including intricate geometries, directly impacts the choice of CNC machine. Multi-axis CNC machining enhances capabilities for complex geometries:

- 3-Axis Machines: These machines suit simpler components.

- 4-Axis Machines: They allow rotation along one additional axis, increasing capability for moderate complexity.

- 5-Axis Machines: These machines provide maximum flexibility for highly complex parts, enabling access to intricate shapes and features.

A part is complex when its structural features exceed the capabilities of simple 3-axis machining. This complexity can arise from:

- Geometry: free-form surfaces, undercuts, steep angles, contoured profiles.

- Tolerances: requirements tighter than ±0.02 mm.

- Thin Walls: walls under 1 mm that risk vibration and deformation.

- Deep Features: deep pockets, narrow channels, or high aspect-ratio cavities.

- Multiple Setups: parts requiring several orientations or coordinated rotary axes.

- Hybrid Features: threads, text engraving, micro-holes, or combined milling/turning requirements.

Such complexities often necessitate multi-axis equipment like 4-axis and 5-axis mills, Swiss-type lathes, and EDM. These machines allow for optimal tool angles, reduced manual repositioning, and precise surface production in difficult-to-reach areas.

| Machining Type | Advantages for Complexity | Limitations for Complexity |

|---|---|---|

| 3-Axis Machining | Best for simple to moderately complex parts; cost-effective for prototypes and production; ideal for flat surfaces, pockets, and basic features. | Cannot reach undercuts or steep angled surfaces; tool access is restricted for deep cavities. |

| 5-Axis Machining | Achieves complex contours in one setup; eliminates repositioning errors; produces smoother surfaces and tighter tolerances; essential for impellers, turbine blades, molds, and medical implants. | Higher equipment cost; requires experienced programmers and machinists. |

| Mill-Turn (Turn-Mill) Centers | Combines high-speed turning with multi-axis milling; enables complete machining in one cycle; reduces setups and improves concentricity; ideal for complex shafts, housings, and hybrid geometries. | N/A |

Complex CNC machined parts, characterized by intricate geometries and tight tolerances, often necessitate multi-axis machining and advanced processes. This directly influences CNC machine selection, as simpler machines cannot handle such complexities.

Precision requirements also vary significantly by industry.

| Industry | Primary Standard | Typical CNC Machining Tolerances |

|---|---|---|

| Aerospace | AS9100 + ASME Y14.5 | ±0.13 mm to ±0.025 mm (±0.005″ to ±0.001″) |

| Medical Devices | ISO 13485 + ASME Y14.5 | ±0.05 mm to ±0.0075 mm (±0.002″ to ±0.0003″) |

Factories producing parts for aerospace or medical devices require machines capable of holding extremely tight tolerances, often demanding higher accuracy and repeatability.

Understanding Project Requirements and Industry Standards

A factory must thoroughly understand its project requirements and adhere to relevant industry standards. These factors dictate specific machine capabilities, quality control processes, and documentation needs.

| Sector | Key Certifications & Compliance |

|---|---|

| Aerospace Industry | AS9100 (extends ISO 9001 with aerospace-specific controls, traceability, and documentation). NADCAP (often mandatory for special processes like heat treating and nondestructive testing). |

| Medical Manufacturing | ISO 13485 (definitive quality management standard for medical devices, covering design, manufacturing, traceability, and risk mitigation). Compliance with FDA 21 CFR Part 820 (Quality System Regulation). |

| Defense Contracting | ITAR (International Traffic in Arms Regulations, strictly controls sensitive technical data and components). ISO 9001 or AS9100 (to demonstrate quality and traceability). |

Compliance with these standards is not optional; it is a prerequisite for operating in these sectors.

| Standard/Certification | Description & Relevance to Sectors |

|---|---|

| ISO 9001 Quality Management | A widely accepted standard for quality management systems, applicable to any business. It ensures continuous delivery of products and services meeting customer and regulatory needs. |

| AS9100 Aerospace Standard | Builds on ISO 9001 with additional requirements specific to aerospace manufacturing, ensuring safety, reliability, and regulatory compliance in aerospace and defense industries. |

| ISO 13485 Medical Devices | An international standard for quality management systems in the design, production, installation, and servicing of medical devices, focusing on safety and effectiveness. |

| ITAR Compliance | US government regulations governing the import and export of defense-related goods and services (USML), essential for companies in defense and aerospace. |

| ISO 14001 Environmental Management | Identifies requirements for an environmental management system, providing a framework to minimize environmental impact and improve environmental performance. |

| ISO 45001 Occupational Health and Safety | Standard for occupational health and safety management systems, providing a framework to identify, control, and minimize workplace health and safety risks. |

A factory must ensure its chosen CNC machine and its associated processes can meet these stringent requirements. This includes considering machine accuracy, repeatability, and the ability to integrate with quality management systems. OTURN MACHINERY, for example, specializes in high-efficiency industrial-special purpose machines and production line solutions for various industrial valve, pipe fitting, flange, construction machinery parts, energy, shipping, molds, and other industries. Their professional team designs for Valve Manufacturing Production Lines, from building a casting assembly line to industrial valve processing machining, valve testing, and welding, demonstrating rich market experience and cases in meeting diverse industry demands.

Evaluating Machine Specifications, Features, and CNC Lathe Considerations

Factories must carefully evaluate machine specifications and features when selecting a CNC drilling and milling machine. This includes considering the type of machining center, the number of axes, spindle capabilities, tool changer efficiency, workholding solutions, and software integration. These factors directly impact a machine’s performance and suitability for specific production tasks, including those that might involve a CNC Lathe.

Vertical vs. Horizontal Machining Centers

The choice between Vertical Machining Centers (VMCs) and Horizontal Machining Centers (HMCs) significantly impacts a factory’s production capabilities. Each type offers distinct advantages for different operational needs.

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Space Occupation | Small footprint, suitable for limited space | Large size, requires more production space |

| Operation | Easy to observe and operate, suitable for smaller/simple parts | Complex operation and maintenance, requires professional technicians |

| Cost | Lower purchase cost, suitable for limited budgets | Higher procurement cost |

| Processing Capacity | Limited for long/heavy parts, stability issues | Stronger for large, heavy, or complex parts, better withstands cutting forces |

| Tool Change Efficiency | Relatively low, especially with frequent changes | More efficient tool change systems |

| Cutting Force | Limited ability to withstand cutting forces | Better at withstanding high cutting forces |

| Cooling System | Standard | More efficient cooling systems |

| Automation | Lower level of automation | Higher level of automation, can integrate with robots |

| Chip Management | Standard | More effective chip discharge due to horizontal design |

| Material Versatility | Wide range (aluminum, plastic, steel) | Suited for high-intensity processing of various materials |

HMCs offer significant advantages in rigidity, productivity, and return on investment (ROI) compared to VMCs. Manufacturers build HMCs more robustly, which leads to less vibration, deflection, and chatter. This makes them ideal for higher volume production and difficult materials like titanium. HMCs typically come equipped with productivity-enhancing options such as 4th axis tombstone capabilities, pallet changers, and high-pressure through-spindle coolant. This configuration allows HMCs to achieve significantly higher spindle utilization, up to 85% compared to an average VMC’s 25%. This means they can produce more parts in less time. While VMCs can be configured with similar options, they often do not perform as effectively due to clearance issues, especially with 4th axis workholding. The higher productivity of HMCs can lead to fewer operators, contributing to better ROI. Some shops even report quoting 25% lower prices with HMCs while maintaining the same profit margins. This enables them to bid on more sophisticated jobs and expand their business opportunities. Therefore, HMCs are best suited for shops that require high volume production, possess the capital to invest, and aim for maximum competitiveness.

Number of Axes for Part Complexity

The number of axes a CNC machine possesses directly correlates with the complexity of parts it can produce. Factories must match the machine’s axis capabilities to their part geometry requirements.

| Machine Type | Best Suited Parts/Operations |

|---|---|

| 3-Axis | Simpler projects, planar milled profiles, drillings, threaded holes in-line with an axis. |

| 4-Axis | Complex geometries, angled features, intricate arcs (like helixes), parts requiring attention from multiple sides, parts with cut-outs and holes on the sides, parts made on cylinders. |

| 5-Axis | Most complex and tedious designs, complete 3-dimensional objects. |

A 3-axis machine creates similar products to 4-axis and 5-axis machines, but with less detail and efficiency. A 5-axis machine creates complete 3-dimensional objects from a block of material. It handles the most complex and tedious designs, delivering high precision and quality.

Spindle Speed, Power, and Torque

Spindle speed, power, and torque are critical specifications. They determine a machine’s ability to efficiently cut various materials. Factories must select a spindle that matches their material processing needs.

| Material Type | Spindle Speed (RPM) | Power (kW) | Torque Characteristics |

|---|---|---|---|

| Soft Metals (e.g., Aluminum, Brass, Copper) | 6,000–18,000 | 3–7.5 | High torque, rigidity, thermal stability |

| Softwoods (e.g., Pine) | 12,000–24,000 (higher speeds for smoother finishes) | 2.2–4.5 | Adequate torque |

| Dense Hardwoods (e.g., Oak, Walnut) | 12,000–24,000 (lower speeds for higher torque) | 2.2–4.5 | Higher torque to avoid burning/chatter |

| Plastics and Acrylics | 18,000–30,000 | 1.5–3 | Moderate power, consistent speed |

| Composites and Carbon Fiber | 12,000–24,000 | 4–6 | Consistent torque across range |

For soft metals like aluminum, brass, and copper, a spindle speed between 6,000 and 18,000 RPM with 3–7.5 kW of power is often suitable. These materials benefit from high torque, rigidity, and thermal stability. Harder materials, such as titanium or hardened steel, require lower spindle speeds but significantly higher torque and power to overcome material resistance without excessive tool wear. Conversely, plastics and acrylics often require higher spindle speeds (18,000–30,000 RPM) but less power (1.5–3 kW) to achieve smooth finishes and prevent melting. The right balance of these factors ensures efficient material removal and optimal tool life.

Tool Changer Capacity and Speed

A machine’s tool changer capacity and speed significantly impact overall production efficiency and cycle times. An efficient tool changer minimizes non-cutting time, which is the period when a machine tool is not actively machining a workpiece. This includes tasks such as replacing parts, changing tools, and delays in machine operation. Addressing both cutting and non-cutting time is crucial for reducing overall cycle time.

Automatic tool changers (ATCs) significantly reduce non-cutting time by enabling seamless tool swaps. This shortens cycle times and increases overall output, particularly in multi-operation tasks. This transforms a stop-and-go machining process into a continuous, programmed workflow. Tool changes occur automatically in a matter of seconds without interrupting the machine’s operation.

| Feature | Without ATC | With ATC |

|---|---|---|

| Production efficiency | Lower due to non-cutting time | Higher due to reduced idle time |

| Suitability for complex parts | Limited – frequent manual changes slow the process | Ideal – supports multiple tools in one cycle |

A precision components shop, using machine monitoring software, discovered that 2.5 minutes of a 12-minute cycle time for a particular part were wasted due to tool change delays. By altering tool paths and switching to a drill and chamfer combination (a multi-function tool), they reduced the cycle time to 9 minutes, achieving a 25% improvement. This freed up nearly 50 machine hours for every 1000 parts produced. Factories can combine operations (e.g., drill + chamfer in one) to reduce tool swaps. They can also switch to multi-function tools or optimize tool sequence if tool change time is high. Smaller machines may hold 12–24 tools. Larger machining centers can support 40, 60, or even more tools.

Workholding and Fixturing Solutions

Effective workholding and fixturing solutions are essential for securing workpieces during machining. They ensure accuracy, repeatability, and operator safety. The choice of solution depends on part geometry, material, and production volume.

| Workholding Solution | Description | Appropriate Use Cases |

|---|---|---|

| CNC Vises | Versatile and common, providing a strong grip. Available in single-station, double-station, and self-centering types. | Milling, drilling, and other machining operations; secure holding with easy adjustments. |

| Magnetic Chucks | Uses magnetic force to secure ferromagnetic materials. | Flat or thin parts where traditional clamping might cause deformation; reduces vibration for machining accuracy. |

| Vacuum Fixtures | Creates suction force to hold non-magnetic and thin materials. | Non-magnetic and thin materials; precision and smooth surfaces; requires a flat, even surface for proper seal. |

| Angle Plates and Clamps | L-shaped devices providing support for workpieces at right angles, combined with clamps. | Machining parts needing to be held perpendicular to the machine bed; securing irregularly shaped parts. |

| Modular Fixture Systems | Customizable workholding setup with interchangeable components like clamps, locators, and supports. | Adapting to different parts without dedicated fixtures; high-mix production; reducing setup time and improving efficiency. |

| Collets and Mandrels | Collets clamp on round parts for precise, centered holding; Mandrels hold from the inside, expanding to grip internal diameter. | Collets: high-speed machining of cylindrical parts on a CNC Lathe. Mandrels: applications requiring precision and repeatability for internal gripping. |

Another common solution is the machine vise, a universal device mounted to the machine table for strong, reliable clamping. It is ideal for prismatic (block-shaped) parts or parts with two parallel sides. Soft jaws, custom jaws typically made of aluminum, are machined to match a specific workpiece contour and fit into a standard vise. They are excellent for irregular shapes, round stock, and repeatable gripping on finished surfaces without damage. Step clamps (toe clamps) utilize T-slots on the machine table for firm holding force. They are suitable for large plates, one-off jobs, and adapt to a wide range of part sizes. Fixture plates (tooling plates) are precision plates with a grid of accurately located mounting and locating holes. They are used for modular or dedicated setups, rapid changeover, and high-mix or medium-volume production. Vacuum chucks create suction over a large surface area to hold parts down. They are ideal for flat, sheet-based materials (metal, composites, plastics) and thin-walled parts prone to distortion, providing unobstructed access to the top surface. For a CNC Lathe, collets and mandrels are particularly important for holding cylindrical workpieces.

CNC Controller and CAD/CAM Software Integration

The CNC controller acts as the machine’s brain, interpreting instructions and executing movements. Seamless integration with CAD/CAM software is crucial for efficient programming and simulation. Leading CNC controller brands are focusing on enhancing user experience through intuitive interfaces, streamlined setup processes, and robust software integrations. Advanced options include touchscreens, mobile compatibility, and cloud-based solutions for real-time data monitoring and remote control. Key performance metrics like processing speed, accuracy, and compatibility with various machine types are crucial. Customizable settings and programmable features are gaining favor, along with the integration of artificial intelligence and machine learning for predictive maintenance and improved operational reliability, signifying a shift towards smart CNC systems.

Several prominent brands offer advanced CNC controllers:

- Heidenhain (Germany): Known for high speed, high precision, and high reliability, with intelligent manufacturing functions for digital production task management.

- Mazak (Japan): Features the MAZATROL SmoothX system with an innovative man-machine interface for improved processing efficiency and intelligent factory integration.

- Mitsubishi (Japan): Offers high-end M700V series for high-precision, high-grade processing, supporting 5-axis linkage for complex surface shapes.

- Haas (America): Provides an easy-to-operate system tailored for Haas machine tools, with intuitive functions for simplified processing and programming.

- Fagor (Spain): The CNC 8070 high-end system can control up to 28 feed axes (linkage), 4 spindles, 4 tool magazines, and 4 execution channels.

- NUM (France): The Flexium+ CNC system can control up to 200 CNC axes and spindles, with each channel interpolating up to 9 axes, and features 40 processing channels and multiple NCK functions.

- Bosch Rexroth (Germany): A world leader in transmission and control, offering expertise in industrial hydraulics, electronic power and control, and linear transmission.

Seamless CAD/CAM software integration offers numerous benefits for programming and simulation.

- Powerful CNC Programming Toolpath Operations: CAD-CAM software enables the creation of complex 3, 4, and 5 Axis toolpaths quickly and efficiently. This would be nearly impossible without it. It also allows for capturing and reusing CAM Tree features, saving significant time.

- Multiaxis CAM Technology Makes Complex Machining Simple and Cost Effective: CAM systems provide full 4 & 5 Axis simulation. This is critical for visually inspecting the machining process before an NC program reaches the machine, making complex programming feasible.

- Seamless Integration with Popular CAD Design Products: Some CAD-CAM providers integrate with popular CAD vendors (e.g., SolidWorks, Rhino) as plug-ins. This allows existing CAD users to create machining, simulate, and generate NC programs without relearning a new system, thus expanding their service offerings.

- Machining Wizards Remove The Guesswork: CAD-CAM provides automation through machining wizards that guide operators through setting cutting depths, selecting tools, choosing toolpath styles, and managing other parameters. This makes programming efficient and reduces errors for both new and advanced programmers.

- Getting The Most Out of Your CNC Machine Tool: CAD-CAM software offers high-speed adaptive toolpath technology that reduces cycle times, tool wear, and machine wear. These toolpaths improve cutting quality by maintaining constant tool engagement, allowing deeper cuts, and increasing CNC machine productivity by over 50%.

- Eliminate Costly Mistakes & Waste: CAD-CAM software includes powerful simulation features that allow visual inspection of the machining process. This catches costly tool gouges and collisions before they occur on the CNC machine. Simulation also provides detailed information on toolpath, cycle times, and part deviation analysis.

CAM systems achieve unparalleled levels of precision through automated toolpath generation, seamless CAD/CAM integration, and virtual simulation. This leads to tighter tolerances, consistent parts, and reduced scrap and rework. They streamline and automate machining processes by eliminating manual programming and optimizing toolpaths, significantly reducing setup times and increasing overall efficiency. This automation saves programming time and ensures peak performance of CNC machines. CAM systems improve accuracy and consistency by relying on precise, computer-generated toolpaths and simulations, eliminating human errors from manual programming. This ensures every part is machined with optimized parameters, improving quality and reducing waste. The seamless CAD/CAM integration allows quick and accurate translation of design intent into machining instructions. Design changes are automatically propagated, saving time, reducing errors, and ensuring the final product reflects the designer’s intent. Modern CAM systems offer virtual prototyping to simulate the machining process before any physical cutting. This allows identification of potential issues like tool collisions, enabling adjustments beforehand, saving time and money, and building confidence for complex projects.

CAD and CAM software can adapt to complex projects, allowing for precise, up-to-scale, repeatable product production quickly and efficiently. They reduce material wastage. Advanced CAD and CAM models outline efficient manufacturing paths, showing tooth paths, cycle times, and potential part deviations to anticipate problems and minimize defects. Rapid prototyping is also possible. CAD and CAM software helps produce prototypes with correct tolerances for testing and sharing rapidly, reducing overall time to production. Enhanced efficiency and product quality result from integrating design and manufacturing software. This helps keep up with evolving consumer demands for efficiency without compromising quality, increasing project turnover. Effective communication and collaboration are also benefits. Integrating CAD and CAM software enables constant communication for product development, leading to higher quality and more innovative products. This applies to both milling machines and a CNC Lathe.

Machine Performance: Accuracy, Rigidity, and Working Envelope

Machine performance hinges on several key attributes: accuracy, rigidity, and the working envelope. These factors collectively determine the quality of parts produced and the machine’s operational efficiency.

In demanding machining applications like high-speed machining (HSM), machine rigidity is essential. A rigid setup minimizes tool deflection. This ensures the tool precisely follows its programmed path, which is critical for achieving high-quality surface finishes and accurate parts. Factors like tailored toolholder designs and stable workholding fixtures enhance rigidity. They reduce vibration and counteract bending forces. This leads to lower cutting forces, reduced heat generation, and consistent adherence to precision standards, ultimately preserving the integrity of both the workpiece and the tool.

Machine condition, particularly its rigidity, significantly influences tool life. A well-maintained and calibrated machine ensures stable cutting. This minimizes vibrations and deflection that lead to premature tool wear. Conversely, a machine lacking rigidity introduces excessive vibration, tool chatter, and inaccurate positioning. This increases forces on the cutting tool. These adverse conditions accelerate tool wear, compromise accuracy, and degrade surface finish quality. Regular maintenance and alignment checks are crucial for optimizing machine conditions and extending tool life.

- Enhanced Surface Finish: High rigidity reduces chatter and vibration, resulting in smoother finishes and higher quality parts with less need for secondary finishing.

- Extended Tool Life: Stable cutting conditions, a direct result of high rigidity, minimize tool wear and breakage, thereby reducing the frequency of tool replacements and operational costs.

Accuracy refers to how closely a machine can achieve a programmed position. Repeatability indicates its ability to return to the same position consistently. High accuracy and repeatability are paramount for industries with tight tolerances, such as aerospace and medical device manufacturing. The working envelope defines the maximum dimensions of a workpiece a machine can handle. Factories must ensure the machine’s working envelope accommodates their largest parts, with sufficient clearance for tool movement and fixturing.

Assessing Investment, Operational Costs, and Manufacturer Support

Factories must consider the financial implications of a CNC machine. This includes initial investment, ongoing operational costs, and the level of manufacturer support. These factors significantly influence the machine’s long-term value and a factory’s profitability.

Initial Purchase Price and Long-Term Operating Costs

The initial purchase price of a CNC machine varies widely. It depends on its capabilities and size.

| Category | Price Range |

|---|---|

| Entry-level CNC milling machines | $10,000 – $30,000 |

| Mid-range CNC milling machines | $30,000 – $100,000 |

| High-end CNC milling machines | $100,000 – $500,000 |

Similarly, CNC drilling machines have different price points.

| Category | Price Range |

|---|---|

| Small-level CNC drilling machine | $10,000 – $50,000 |

| Industrial CNC drilling system | $50,000 – $250,000 |

Beyond the initial cost, factories must evaluate long-term operating expenses. These include energy consumption, cooling requirements, and consumables. Maintenance and service also contribute to these costs. Energy efficiency plays a crucial role. Superior tools require less energy and reduce wear on machinery. This decreases utility costs.

The chart illustrates how optimized machines can significantly reduce annual electricity, 5-axis operation, and HVAC & maintenance costs.

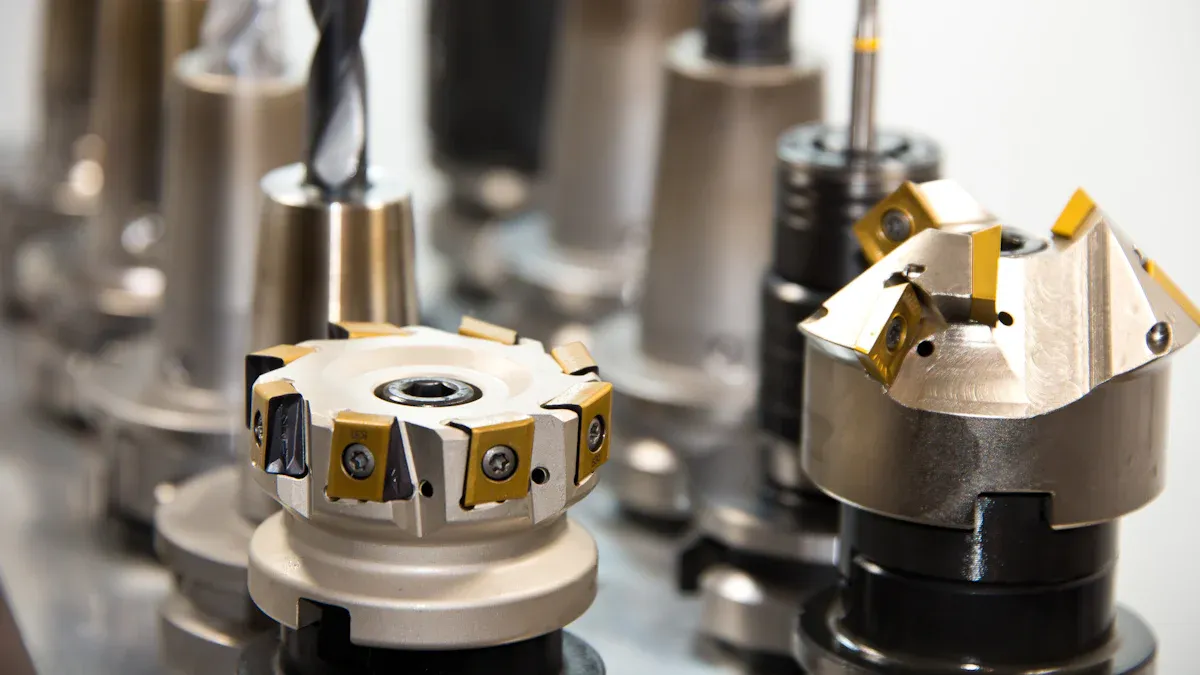

Tooling, Accessories, and Training Investments

Factories need to invest in essential tooling and accessories for a new CNC machine setup. These include:

- Through-spindle coolant: Crucial for large-diameter drilling or boring.

- Zero-point clamping systems: Enhance repeatability and allow multi-step machining.

- Presetters: Enable offline measurements, keeping spindles running.

- Automated, intelligent tool management systems: Provide deep traceability.

- Digital tools: Facilitate easier machine adjustments and reduce human error.

- Tool Holders: Essential for high-pressure, through-tool coolant systems.

- Boring tools: A key tooling category.

- Workholding: An important accessory category.

Involving a trusted tooling partner early helps integrate machine specifications and tooling packages effectively. This ensures crucial options like through-spindle coolant are considered from the outset. Factories also need to invest in training. Mitsubishi Electric Automation offers CNC Programmer Certification focusing on G-code programming for Mill and Lathe. Penn Foster provides online CNC Operator Training covering safety, basic math, machining skills, and CNC programming fundamentals.

Return on Investment and Machine Lifespan

Factories aim to maximize return on investment (ROI) and machine lifespan. Several factors contribute to a longer machine life and better ROI:

- Optimizing Cutting Parameters: Adjusting spindle speed, feed rate, and depth of cut prevents tool wear and overheating.

- Leveraging Advanced CAM Software: This software simulates machining processes and optimizes toolpaths.

- Advanced Machining Techniques: High-speed machining (HSM) and multi-axis machining lead to faster cycle times and less heat generation.

- Proper Workpiece Setup and Machine Maintenance: Spindle alignment and vibration control are essential for maintaining accuracy.

- Effective Cooling and Lubrication Systems: These systems protect tools and workpieces by reducing heat and friction.

- Real-Time Monitoring and Adjustments: Smart sensors and digital twin simulations allow early detection of issues.

After-Sales Service, Technical Support, and Warranty

Comprehensive after-sales service and a robust warranty are crucial. Key aspects of a CNC machine warranty include:

- Comprehensive Coverage: It covers all major machine components.

- Clear Terms: It defines what is and is not covered.

- Reliable Support: It provides access to qualified technical support.

- Quality Assurance: It guarantees a certain level of machine performance.

- Flexibility for Upgrades: It offers options for upgrades.

- Transferability: This is valuable if the machine is resold.

- No-Fault Coverage: It may cover accidental damage.

- Software Updates: It includes software updates and support.

- On-Site Service: It provides on-site service and repairs.

Standard warranty periods for CNC drilling machines typically span one to three years. Some manufacturers, especially for high-end models, may extend warranties up to five years. EMAG offers various service contracts, from basic inspection to full-service agreements. These contracts reduce unplanned downtimes and ensure optimum machine availability.

Availability of Spare Parts and Customer Reviews

The availability of spare parts is vital for minimizing downtime. Lead times for critical spare parts vary. Simple parts can often be delivered within 1-2 weeks. More complex components or larger orders can extend lead times to 4-6 weeks or longer. Material availability, part complexity, quantity, and supplier capacity all influence the final lead time.

Prospective buyers can find reliable customer reviews and testimonials on websites like STYLECNC and TechnoCNC. These platforms collect genuine feedback from customers who have purchased and used various CNC machine types. This helps factories make informed decisions.

Factories must prioritize a CNC machine that meets current production demands. This machine should also support future growth. Ensure the chosen equipment optimizes production efficiency. It must deliver long-term value to the factory. This strategic selection drives profitability.

FAQWhat is the main difference between a Vertical Machining Center (VMC) and a Horizontal Machining Center (HMC)?

VMCs are compact and suitable for simpler parts. HMCs offer higher rigidity and productivity for complex, high-volume production. They handle heavier parts better.

Why is the number of axes important for a CNC machine?

The number of axes determines part complexity. More axes allow for intricate geometries, angled features, and complete 3D objects in fewer setups.

How does CAD/CAM software improve CNC machining?

CAD/CAM software streamlines programming, simulates processes, and optimizes toolpaths. This reduces errors, saves time, and enhances precision and efficiency.

Media Contact

Company Name: SHANGHAI OTURN MACHINERY CO., LTD.

Contact Person: Media Relations

Email:Send Email

Country: China

Website: https://www.oturnmachinery.com/