Project Background

A U.S.-based environmental company specializing in exhaust gas purification and biogas desulfurization planned to upgrade its existing packed column. The goal was to replace random packing with a high-efficiency structured packingsystem that would provide low pressure drop, excellent corrosion resistance, and improved Mass Transfer performance.

Solution

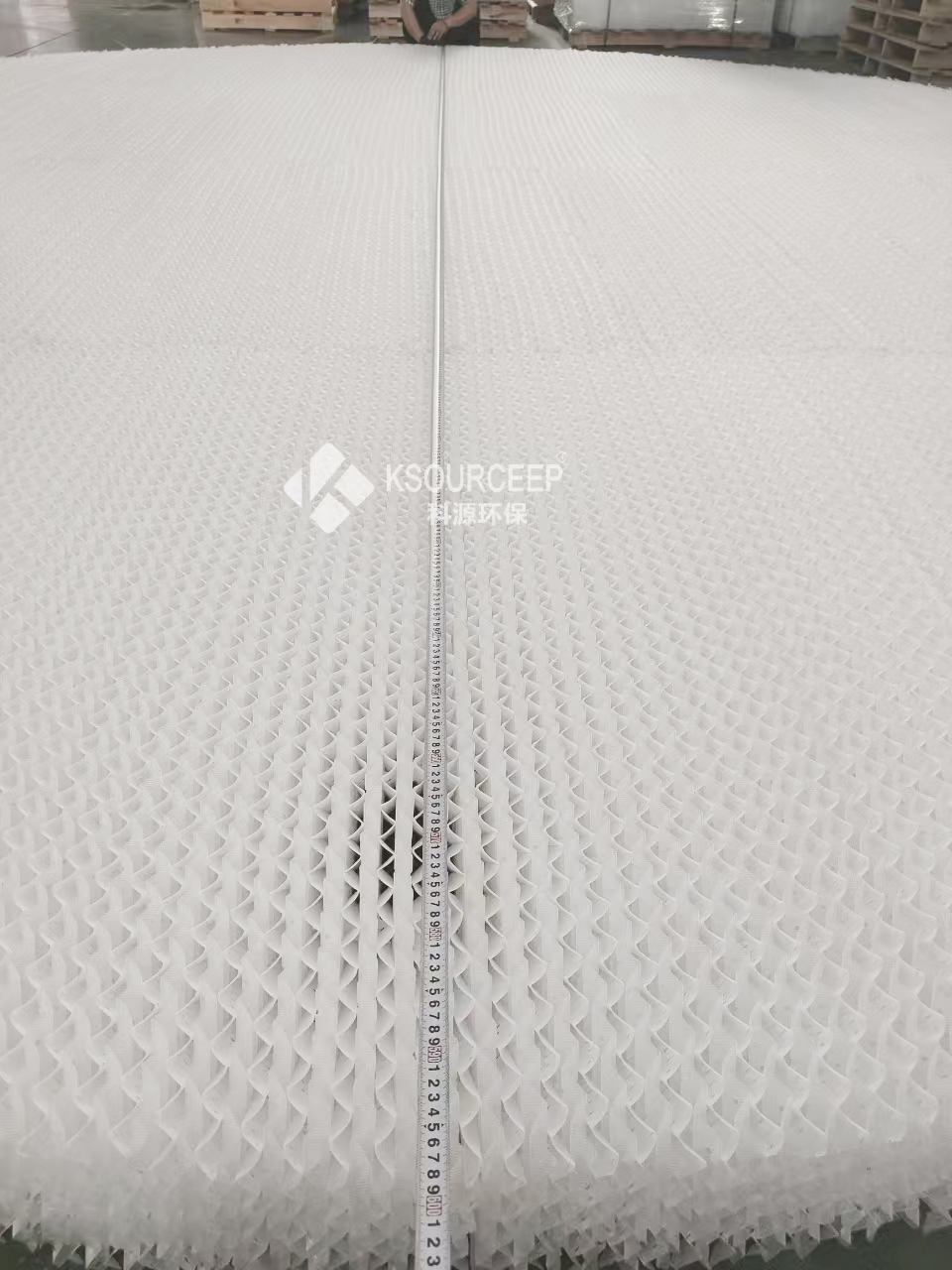

Based on the operating conditions (mixed H₂S and CO₂ gas with alkaline liquid, tower diameter 1000mm), we recommended the 125Y PP perforated corrugated structured packing, which offers:

- High specific surface area (approx. 125 m²/m³)for efficient Mass Transfer;

- Perforated surface design that enhances liquid distribution and wetting;

- Lightweight and corrosion-resistant PP material suitable for alkaline and acidic environments;

- Ideal for wet desulfurization, gas absorption, condensation, and demisting systems.

Performance Results

After commissioning, the client reported:

- 25% reduction in column pressure drop;

- H₂S removal efficiency exceeding 98%;

- Stable operation with no flooding or clogging;

- Maintenance intervals doubled compared with previous packing.

Client Feedback

“The Pp Structured Packing performed excellently in our absorber tower. It’s lightweight, easy to handle, and significantly improved our mass transfer efficiency.” — Project Engineer

We offer customization in various sizes, colors, and materials to suit your application needs.

Feel free to contact us for technical data and tailored solutions!

Media Contact

Company Name: Pingxiang Ksource Chemical Packing Co., Ltd.

Email:Send Email

Country: China

Website: https://www.ksourcepacking.net/