1. What is an EN593 butterfly valve?

An EN593 butterfly valve refers to a metal butterfly valve designed and manufactured in accordance with the BS EN 593:2017 standard, titled “Industrial Valves - General Metal Butterfly Valves.” This standard is published by the British Standards Institution (BSI) and aligns with European standards (EN), providing a comprehensive framework for the design, materials, dimensions, testing, and performance of butterfly valves.

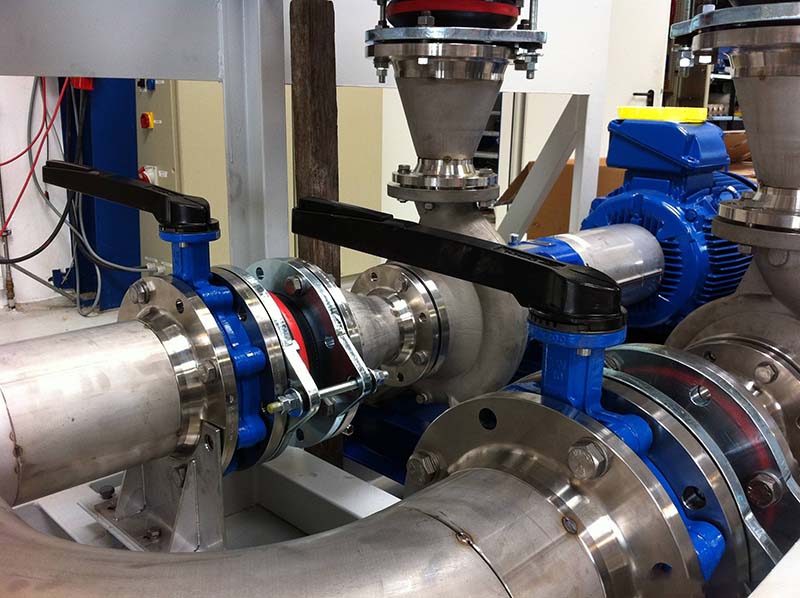

EN593 butterfly valves are characterized by their metal valve bodies and various connection methods, such as wafer-type, lug-type, or double-flanged. These butterfly valves can operate under different pressure and temperature conditions. This standard ensures that valves meet stringent requirements for safety, durability, compatibility, and reliability.

2. Key Features of EN593 Butterfly Valves

* Quarter-turn operation: Butterfly valves operate by rotating the valve disc 90 degrees, enabling rapid and efficient flow control.

* Compact design: Compared to gate valves, ball valves, or globe valves, butterfly valves are lightweight and space-saving, making them ideal for installations with limited space.

* Diverse end connections: Available in wafer, lug, double flange, single flange, or U-type designs, compatible with various piping systems.

* Corrosion resistance: Constructed from high-quality corrosion-resistant materials to ensure durability in corrosive environments.

* Low torque: Designed to reduce torque requirements, enabling automation with smaller actuators and lowering costs.

* Zero-leakage sealing: Many EN593 valves feature elastic soft seats or metal seats, providing bubble-tight sealing for reliable performance.

3. BS EN 593:2017 Standard Details

As of 2025, the BS EN 593 standard adopts the 2017 version. EN593 is a comprehensive guide for metal butterfly valves, specifying minimum requirements for design, materials, dimensions, and testing. The following is a detailed introduction to the main content of the standard, supported by industry data.

3.1. Scope of the standard

BS EN 593:2017 applies to metal butterfly valves for general purposes, including isolation, regulation, or control of fluid flow. It covers various types of valves with pipe end connections, such as:

* Wafer-type: Clamped between two flanges, featuring a compact structure and lightweight design.

* Lug-type: Features threaded insertion holes, suitable for use at pipe ends.

* Double-flanged: Features integral flanges, directly bolted to pipe flanges.

* Single-flanged: Features integral flanges along the valve body's central axis.

* U-type: A special type of wafer-type valve with two flange ends and compact face-to-face dimensions.

3.2. Pressure and Size Range

BS EN 593:2017 specifies the pressure and size ranges for butterfly valves:

* Pressure ratings:

- PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160 (European pressure ratings).

- Class 150, Class 300, Class 600, Class 900 (ASME pressure ratings).

* Size range:

- DN 20 to DN 4000 (nominal diameter, approximately 3/4 inch to 160 inches).

3.3. Design and Manufacturing Requirements

This standard specifies specific design criteria to ensure the reliability and performance of the valve:

* Valve body material: Valves must be manufactured from metallic materials such as ductile iron, carbon steel (ASTM A216 WCB), stainless steel (ASTM A351 CF8/CF8M), or aluminum bronze (C95800).

* Valve disc design: The valve disc may be centerline or eccentric (offset to reduce seat wear and torque).

* Valve seat material: Valve seats may be made of elastic materials (such as rubber or PTFE) or metallic materials, depending on the application. Elastic seats provide zero-leakage sealing, while metallic seats must also withstand high temperatures and corrosion in addition to achieving zero leakage.

* Face-to-face dimensions: Must comply with EN 558-1 or ISO 5752 standards to ensure compatibility with piping systems.

* Flange dimensions: Compatible with standards such as EN 1092-2 (PN10/PN16), ANSI B16.1, ASME B16.5, or BS 10 Table D/E, depending on the valve type.

* Actuator: The valves can be manually operated (handle or gearbox) or automatically operated (pneumatic, electric, or hydraulic actuator). The top flange must comply with ISO 5211 standards to enable standardized actuator installation.

3.4. Testing and Inspection

To ensure quality and performance, BS EN 593:2017 requires rigorous testing:

* Hydraulic pressure test: Verifies that the valve is leak-free at specified pressure.

* Operational test: Ensures smooth operation and appropriate torque under simulated conditions.

* Leakage Test: Confirm bubble-tight sealing of the elastic valve seat according to EN 12266-1 or API 598 standards.

* Inspection Certificate: The manufacturer must provide test and inspection reports to verify compliance with standards.

3.5. Applications of EN593 Butterfly Valves

* Water Treatment: Regulate and isolate the flow of various freshwater, seawater, or wastewater. Corrosion-resistant materials and coatings make them suitable for harsh environments.

* Chemical and Petrochemical Industries: Handling corrosive fluids such as acids, alkalis, and solvents, benefiting from materials like PTFE seats and PFA-lined valve discs.

* Oil and Gas: Managing high-pressure, high-temperature fluids in pipelines, refineries, and offshore platforms. The double-offset design is favored for its durability under these conditions.

* HVAC systems: Controlling the flow of air, water, or refrigerant in heating and cooling systems.

* Power generation: Regulating steam, cooling water, or other fluids in power plants.

* Food and pharmaceutical industries: Using FDA-compliant materials (such as PTFE and WRA-certified EPDM) to ensure contamination-free operation and meet hygiene standards.

3.6. Maintenance and Inspection

To ensure long-term performance, EN593 butterfly valves require regular maintenance:

* Inspection frequency: Inspect every six months to one year for wear, corrosion, or operational issues.

* Lubrication: Reduce friction and extend valve lifespan.

* Valve Seat and Seal Inspection: Verify the integrity of elastic or metal valve seats to prevent leaks.

* Actuator Maintenance: Ensure pneumatic or electric actuators are free of debris and operate normally.

4. Comparison with Other Standards API 609

While BS EN 593 is applicable for general industrial use, it differs from the API 609 standard, which is specifically designed for oil and gas applications. Key differences include:

* Application focus: API 609 focuses on oil and gas environments, while BS EN 593 covers a broader range of industries, including water treatment and general manufacturing.

* Pressure ratings: API 609 typically covers Class 150 to Class 2500, while BS EN 593 includes PN 2.5 to PN 160 and Class 150 to Class 900.

* Design: API 609 emphasizes corrosion-resistant materials to withstand harsh conditions, while BS EN 593 allows for more flexible material selection.

* Testing: Both standards require rigorous testing, but API 609 includes additional requirements for fire-resistant design, which is critical in oil and gas applications.

5. Conclusion

| Feature | Key Aspects Defined by EN 593 |

| Valve Type | Metallic butterfly valves |

| Operation | Manual, gear, pneumatic, electric |

| Face-to-Face Dimensions | As per EN 558 Series 20 (wafer/lug) or Series 13/14 (flanged) |

| Pressure Rating | Typically PN 6, PN 10, PN 16 (can vary) |

| Design Temperature | Dependent on materials used |

| Flange Compatibility | EN 1092-1 (PN flanges), ISO 7005 |

| Testing Standards | EN 12266-1 for pressure and leakage tests |

The BS EN 593:2017 standard provides a robust framework for the design, manufacture, and testing of metal butterfly valves, ensuring their reliability, safety, and performance across a wide range of applications. By adhering to the standard's requirements for pressure ratings, size ranges, materials, and testing, manufacturers can produce valves that meet global quality benchmarks.

Whether you need wafer-type, lug-type, or double-flanged butterfly valves, compliance with the EN 593 standard ensures seamless integration, durability, and efficient fluid control.

Media Contact

Company Name: Tianjin Zhongfa Valve Co., Ltd.

Email:Send Email

Phone: +86 13212024235

Address:No.38, Baoyuan Road, Jinnan Economic Development Zone, Jinnan District

City: Tianjin

Country: China

Website: https://www.zfavalve.com/