Redefining Crinkle with 3D Elegance & Technical Precision

A New Standard in Textural Aesthetics

GrandStar’s advanced fabric development team has reimagined the traditional crinkle concept with an elegant new approach. The result? A next-generation Crinkle fabric that marries three-dimensional wrinkle texture with lace-like floral edge motifs, creating a refined, high-end appearance ideal for premium fashion applications.

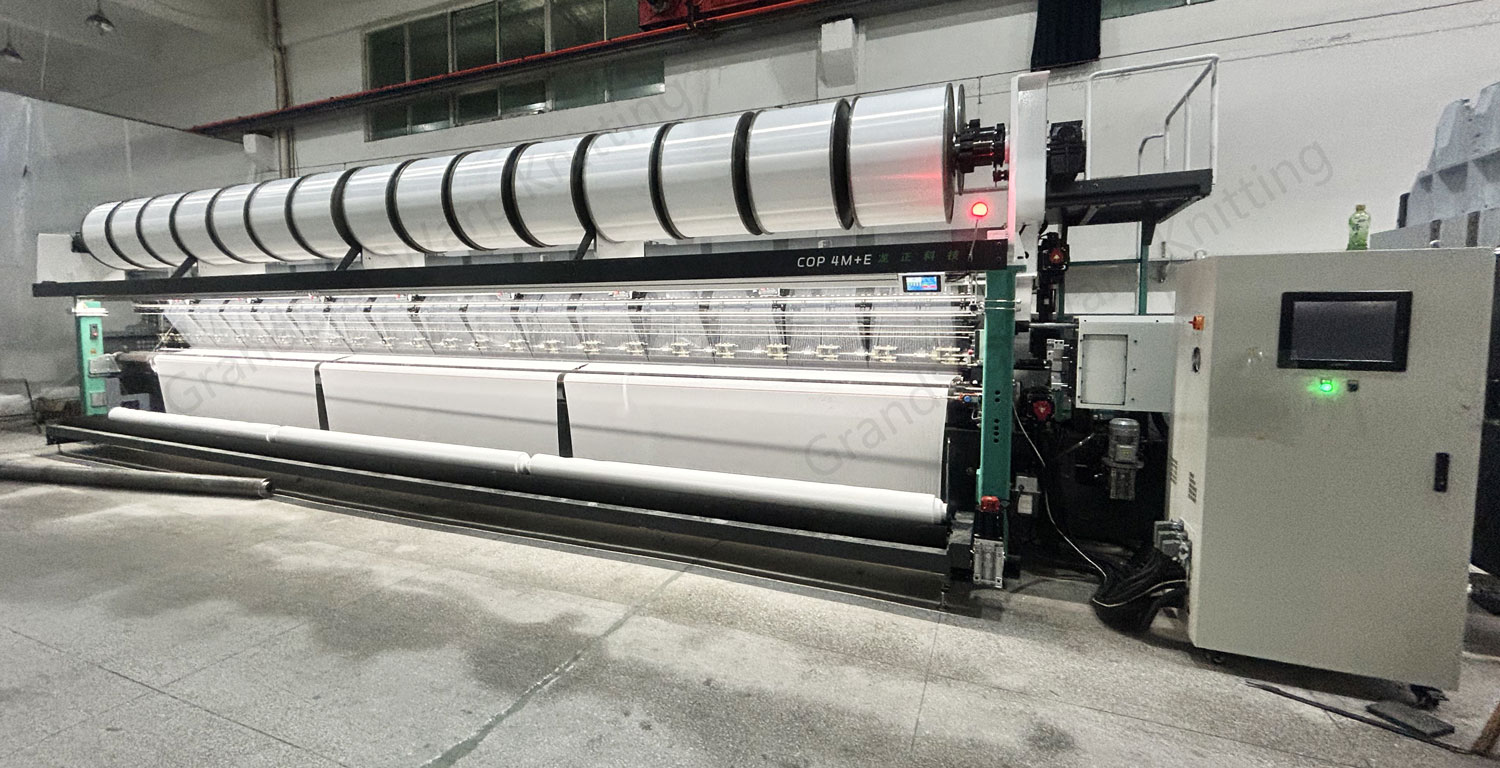

Inspired by extensive R&D and fabric testing, this development showcases the full potential of GrandStar’s HKS4 EL warp knitting platform. Leveraging fine-gauge E28 configuration, our engineers crafted a fabric that transcends the ordinary — achieving softness, resilience, and visual depth.

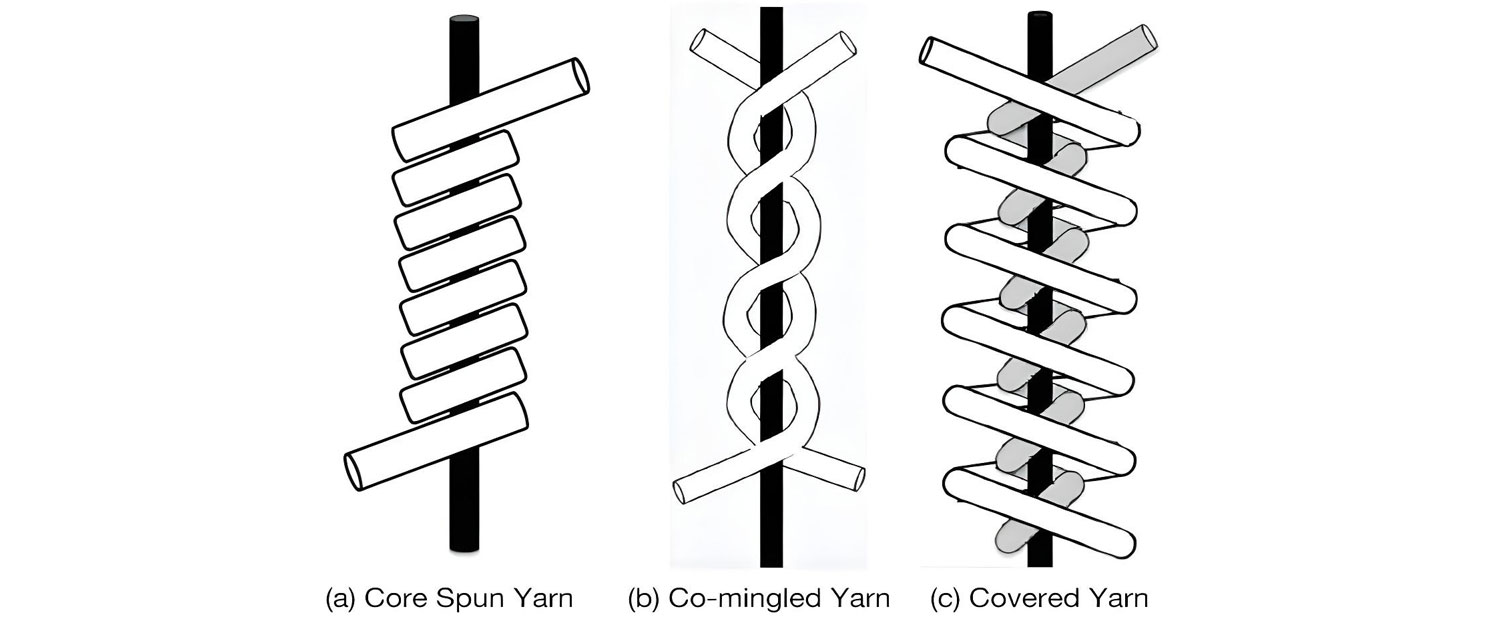

Engineered for Performance: The Role of Core-Spun Yarn

At the heart of this innovation lies the use of core-spun yarn, combining polyamide (nylon) sheathing with a spandex (elastane) core. This pairing brings multiple technical benefits:

- Durability: The polyamide outer layer protects the spandex core from abrasion during wear and washing.

- Color Uniformity: Excellent coverage avoids elastane “grinning” after dyeing, ensuring rich coloration.

- Process Stability: Elasticity helps balance yarn tension fluctuations caused by structural variation.

This construction ensures mechanical reliability and maintains visual integrity even in dynamic design transitions.

Visual Contrast Through Transparent & Opaque Patterning

The fabric’s distinctive rhythm stems from alternating sheer mesh and dense zones, engineered on the GrandStar HKS4 EL machine. Key features include:

- GB 1 and GB 2: Use core-spun yarn to form structured zigzag motifs enhanced by inlay loops and directional floating yarns.

- GB 3 and GB 4: Knit with ultra-fine 40D10f nylon to create mesh and dense fields via customized threading.

- Front Bar: Enhances arched transitions and curve dynamics, adding surface depth and definition.

Combined with advanced threading and inlay techniques, these elements generate refined arch-like embossing and sharp border contrasts — the essence of the crinkle-lace effect.

Crinkle Fabric: Market Potential & Future Development

The new Crinkle fabric is not just an experimental concept — it’s a breakthrough with broad commercial implications. Early feedback from the market has been overwhelmingly positive:

“Crinkle fabric always adds depth to a collection — but this version is a true standout. The way delicacy meets dimension is something entirely new.”

— Fashion Buyer, European Intimates Market

Potential application areas include:

- Lingerie and Intimates

- Luxury Casualwear

- Home Decor Textiles

Why GrandStar Leads in Warp-Knitted Fabric Innovation

Compared to traditional warp knitting manufacturers, GrandStar provides an unmatched advantage through tight integration between machine technology and fabric R&D:

- Machine-Matched Material Design: Fabric is co-developed to match HKS series architectures perfectly.

- End-to-End Testing: In-house lines simulate production to ensure tension, loop stability, and dyeing outcomes.

- Customization Support: Our team can replicate or tailor designs for your unique product needs.

With innovations like the Crinkle fabric, GrandStar proves why it remains at the forefront of the warp knitting industry — from concept to commercial production.

Ready to Transform Your Next Collection?

Contact our team today to explore how GrandStar’s advanced fabric innovations can elevate your product lines.

Media Contact

Company Name: Fujian Grand Star technology Co., Ltd

Email:Send Email

Country: China

Website: https://www.grandstarcn.com/