Yangzhou, China - July 15th, 2025 - For over three decades, HUADA MESH BELT (Since 1992) has been a trusted name in industrial thermal processing solutions. Today, we announce a pivotal step in our global expansion: supplying custom-engineered SUS 310S wire mesh belts to a renowned European powder metallurgy (PM) enterprise. While formal collaboration is pending sample validation, our confidence in these belts—crafted for extreme durability and precision—underscores our commitment to redefining industry standards.

30 Years of Expertise, Now Serving Europe’s Premier PM Manufacturers

HUADA MESH BELT isn’t just another conveyor belt supplier. With roots tracing back to 1992, we’ve spent over 30 years refining our craft, serving industries from aerospace to renewable energy. Unlike budget-focused competitors that prioritize low costs, we invest in premium materials (e.g., SUS 310S stainless steel, Cr20Ni80 high temperature alloy) and precision engineering to deliver belts that outlast, outperform, and outvalue generic alternatives.

Today, our high temperature wire conveyor belts andconveyor mesh belts are sought after by global OEMs—including a growing number of European PM enterprises—seeking solutions for high-temperature sintering, annealing, and powder compaction.

Sample Phase: Two Precision-Engineered SUS 310S Belts for Validation

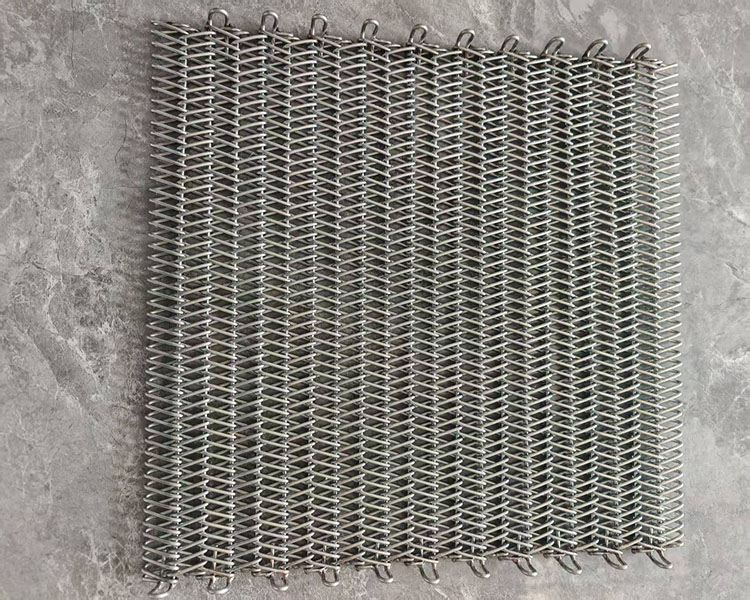

To meet the European client’s exacting requirements, we’ve developed two custom SUS 310S wire mesh belt samples, each tailored to specific sintering profiles:

Sample 1: High-Density Packing for Heavy-Duty Compaction

- Spiral Wire Diameter: 3.0mm (spiral wire)

- Cross Wire Diameter: 3.77mm (cross wire)

- Mesh Size: 7.26mm × 20.33mm

- Key Feature: Dense wire arrangement minimizes material deformation during high-pressure compaction, ideal for dense powder metallurgy parts.

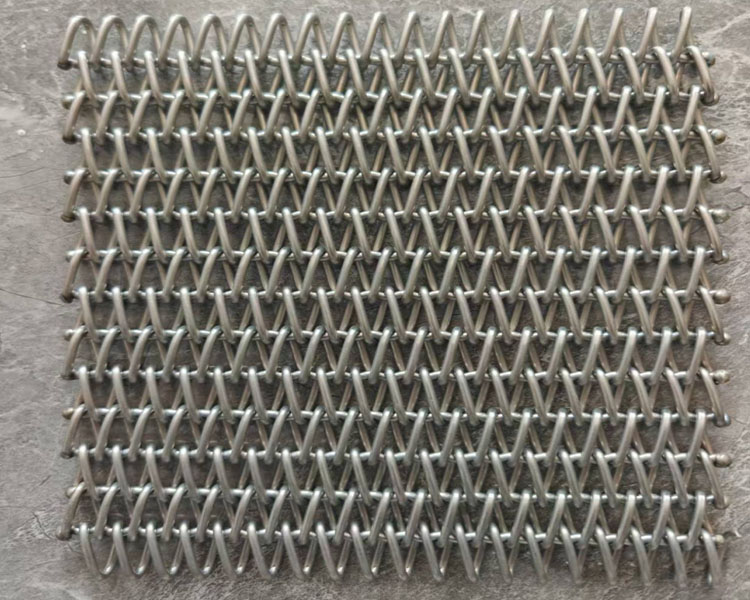

Sample 2: Optimized Airflow for Uniform Heating

- Spiral Wire Diameter: 2.68mm (spiral wire)

- Cross Wire Diameter: 3.77mm (cross wire)

- Mesh Size: 7.26mm × 20.33mm

- Key Feature: Wider spiral wire spacing enhances airflow distribution, reducing hotspots and improving sintering uniformity in large-scale furnaces.

Both samples are crafted from SUS 310S stainless steel—renowned for its exceptional oxidation resistance (up to 1,100°C) and mechanical strength under thermal stress. Unlike generic belts, our SUS 310S wires undergo strict quality checks to ensure ±0.02mm dimensional consistency, eliminating clogging risks and energy waste.

Why Choose HUADA? Quality Over Price, Always

In an industry where many manufacturers cut corners to lower costs, HUADA stands apart:

- Material Integrity: Our SUS 310S belts contain 24–26% chromium and 19–22% nickel, far exceeding industry minimums, ensuring creep resistance and longevity in cyclic thermal environments.

- Precision Manufacturing: CNC-controlled weaving technology guarantees uniform wire spacing (±0.05mm) and surface brightness, reducing maintenance downtime by up to 40% compared to budget belts.

- Proven Durability: Field data from our global clients shows HUADA belts last 2–3times longer than standard alternatives—even in aggressive PM sintering cycles involving 1,100°C holds.

“We’re not here to compete on price,” says Mr. Cao, HUADA’s Owner. “Our 30-year reputation is built on one thing: delivering belts that work, day in and day out. These samples are a testament to that.”

Global Momentum: From Samples to Long-Term Partnerships

While we’re in the sample validation phase with this European PM leader, HUADA’s conveyor mesh belts are already powering innovation worldwide:

- A U.S. aerospace manufacturer reduced energy costs by 18% using our SUS 310Swire mesh belt in titanium alloy sintering lines.

- A German automotive supplier achieved zero-defect throughput for 6,000+ hours with our high-density wire meshbelt

These partnerships reflect a growing industry trend: manufacturers are prioritizing quality and reliability over short-term cost savings.

We invite the European PM enterprise—and all industrial leaders—to experience the HUADA advantage. Our team is ready to:

- Provide full technical documentation (material certificates, thermal test reports).

- Arrange on-site sample testing in your facility.

- Customize belt specifications (wire diameter, mesh size, surface coatings) to match your exact needs.

Media Contact

Company Name: Jiangsu Huada Metal Mesh Belt Co., Ltd.

Email:Send Email

Country: China

Website: https://www.globalmeshbelt.com/