King Machine, a leader in beverage packaging solutions, continues to set new standards in the industry with its advanced range of rinsing, filling, and capping monoblock machines. With an unmatched focus on performance, versatility, and hygiene, King Machine is positioning itself as a trusted partner in the rapidly evolving global beverage market.

The company’s portfolio includes filling solutions for a wide array of beverages, including still and carbonated water, soft drinks, milk and dairy products, beer, sports and energy drinks, tea, and juice. As the demand for high-performance and flexible filling technologies grows, King Machine remains committed to delivering exceptional machinery that ensures the highest quality standards.

Versatile and High-Capacity Monoblock Machines

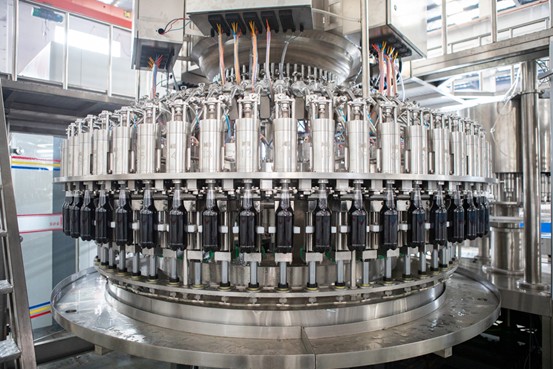

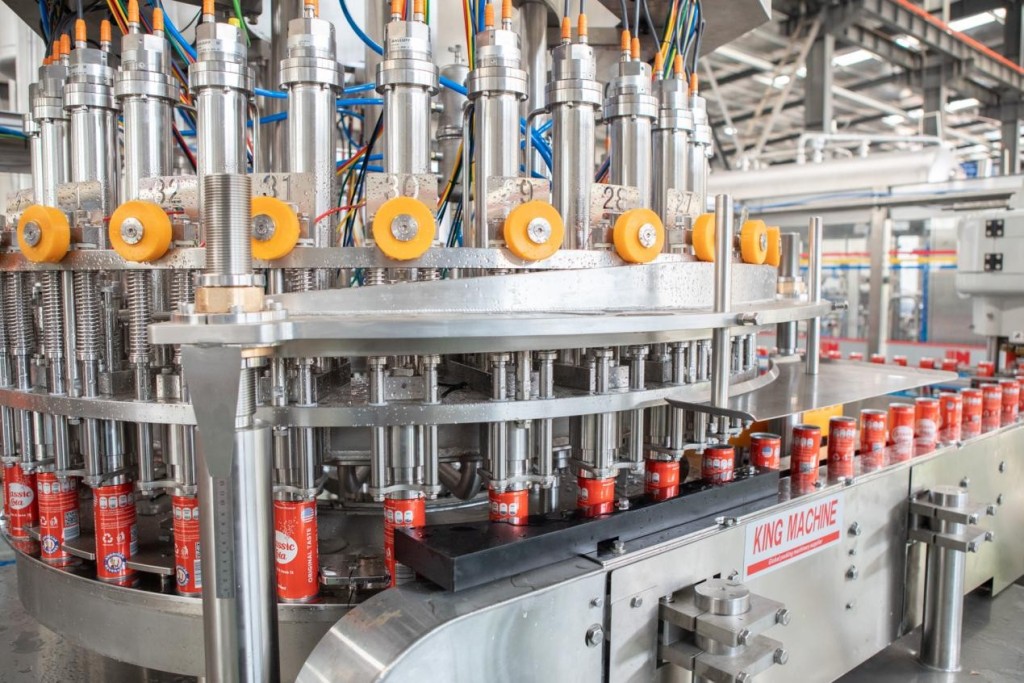

King Machine’s range of monoblock machines is designed to meet the diverse requirements of modern beverage production lines. These systems are capable of handling a wide variety of products, from still water to carbonated soft drinks, juices, beer, and even functional beverages. Key features of King Machine’s filling lines include:

- Ultra Hygienic Systems: The company’s filling and capping solutions are designed for extreme sanitation, ensuring safe and clean bottling for sensitive beverages such as milk, juices, and alcohol.

- High-Capacity Output: Machines are available with capacities ranging from 2,000 to 54,000 bottles per hour (bph), with customizable options for bottle sizes, including 0.33L to 1L bottles.

- Easy Maintenance and Quick Changeovers: King Machine’s monoblocks are designed to reduce downtime, with quick size changes and simple maintenance procedures that ensure consistent production efficiency.

Comprehensive Filling Solutions for Every Beverage Type

King Machine offers a comprehensive range of filling solutions tailored to specific product needs:

- Gravity Filling Monoblocks: Ideal for mineral water, juices, tea, sports drinks, and functional beverages. These machines provide a filling capacity of 3,000 to 54,000 bph for 0.5L still water and fruit juice, with models featuring up to 100 valves for high productivity.

- Electronic Volumetric Filling Monoblocks: Designed for carbonated beverages (CSDs), still water, juices (including pulpy varieties), and sensitive products like fresh or micro-filtered milk. These systems feature magnetic flow meter valves for precise product dosing, stainless steel bases, and user-friendly touch screen interfaces.

- Isobaric Filling Monoblocks: Specifically built for carbonated mineral water, CSDs, and beer, these machines offer speeds of 2,000 to 30,000 bph for 0.5L bottles at 5°C, with options for semi-electronic and pneumatic electro-filling valves.

- Pneumatic Electro-Filling Valve / Mechanical Filling Valve Monoblocks: Suitable for sparkling water, CSD, soda water, and beer, with capacities ranging from 1,000 to 35,000 bph for 200ml to 1L bottles. These machines are designed for a broad range of carbonated beverages and other liquids.

- Electronic Weight Fillers: Ideal for packaging edible oils, liquid food products, sauces, detergents, and personal care items. These fillers can operate at speeds of 3,000 to 50,000 bph, with precise weight-based filling systems that ensure product accuracy.

- Piston Filling Monoblocks: Designed for chemicals and daily-use products like detergents, shampoos, liquid soaps, and cleaners. These fillers cater to a variety of container types, including PE and PP bottles, with capacities from 6 to 24 valves.

- Flowmeter Filling valve: The filling machine is equipped with high precision flowmeter aboved each filling valve pipeline. when the machine is designed , a parameter package is set on the electrical control system for each capacity. each valve filling volume can be set through the touch screen, filling capacity accuracy can reached 2‰, in the process of filling, filling valve and bottle neck do not contacvt , so filling process is very clean , without second pollution. the filling valve opening and closing by cylinder which controlled by soleniod valve, the first rapid filling and stay for a while to certain amount and then switch to slow filling.

- Negative pressure filling valves: High-quality 304 stainless steel liquid barrels, Pneumatic liquid inlet, Connected CIP cleaning dummy cup, Independent negative pressure back suction tank, Quick-change bottle in and out dial wheel, 304 stainless steel panel and shield, Bottle jamming overload protection.

- Float-ball cylinder type volumetric filling: The third generation of king machine can filling machine. It is characterized by compact structure and very convenient maintenance and operation. However, the remarkable feature is that the filling machine is equipped with floating ball measuring cylinder electronic pneumatic valve. It is the most first-class technology for gas filling of cans in the world. It adopts floating ball measuring cylinder fixed volume filling. The filling process is controlled by electronic valve and the filling capacity is constant.

Revolutionizing Beverage Production with Advanced Technology

King Machine’s filling monoblocks are engineered to provide maximum efficiency, reduce operational costs, and ensure the highest level of hygiene and precision. Whether for carbonated or still beverages, functional drinks, or more sensitive liquids, King Machine’s equipment is built to support production scalability and adapt to changing market demands.

“We are proud to offer an extensive range of monoblock filling machines that meet the evolving needs of the beverage industry,” said a company spokesperson at King Machine. “Our technology not only ensures top-tier product quality and hygiene but also offers manufacturers flexibility and cost savings through efficient design and high-performance output.”

About King Machine

King Machine is a global leader in beverage packaging and filling solutions, offering state-of-the-art technology for liquid filling, capping, and rinsing systems. The company’s products serve a wide range of industries, including beverage, dairy, chemicals, and personal care. With a strong emphasis on innovation, reliability, and customer satisfaction, King Machine provides cutting-edge solutions that enhance productivity and maintain the highest hygiene standards in beverage packaging.

For more information on King Machine’s products and services, visit King Machine.

Media Contact

Company Name: King Machine

Contact Person: Joyce Xu

Email:Send Email

Phone: +86-13606220224

Country: China

Website: www.king-machine.com