In high-voltage power systems, safety and efficiency are paramount. Overload protection, particularly in transformers, is essential to prevent damage and ensure uninterrupted operation. One critical component that provides this protection is the bayonet fuse holder, specifically the Bay-O-Net assembly. This device plays a crucial role in safeguarding transformers and electrical equipment from overcurrent and short circuits, helping to maintain the reliability of the entire electrical system.

This article delves into the specifics of the Bay-O-Net assembly, its features, functionality, and the types of fuses it works with. We will also explore the importance of bayonet fuse holders in protecting high-voltage power systems and transformers.

What Is a Bayonet Fuse Holder?

A bayonet fuse holder is an essential device used to hold and secure fuses in high-voltage power systems. It is designed for ease of installation and replacement, providing a simple but effective method of fuse management in transformers and other high-voltage electrical equipment. The bayonet mechanism ensures a secure connection, protecting the fuse from environmental factors such as oil, dust, and moisture.

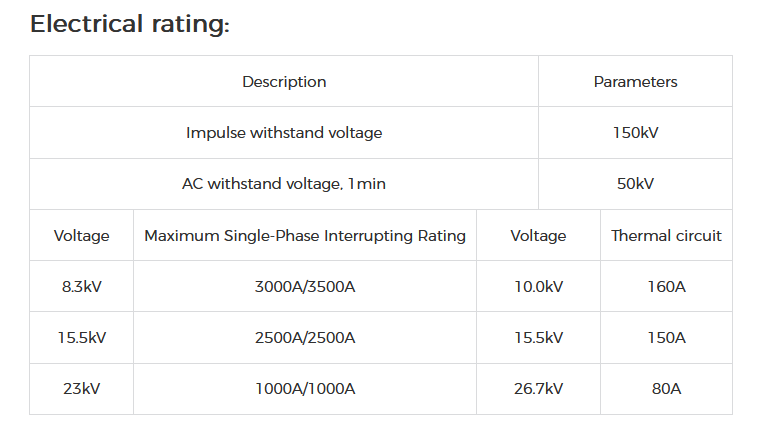

Bayonet fuse holders are typically used in conjunction with current-sensing fuses and dual-element fuse wires, which provide protection from both overload and short circuits. These holders are designed to house fuses that can operate in conditions with a voltage rating of up to 15.5 kV and current ratings of up to 140A.

Understanding the Bay-O-Net Assembly

The Bay-O-Net assembly is a specialized version of the bayonet fuse holder that is used primarily in oil-filled transformers. It is a compact and efficient device designed to offer safe, high-efficiency protection based on current load and oil temperature.

When a fuse wire is installed in the Bay-O-Net assembly, it provides both current sensing and temperature-based protection for the transformer. This dual functionality ensures that the equipment is shielded from dangerous overcurrent conditions and potential overheating, which could cause transformer failure or extensive damage.

The Bay-O-Net assembly is suitable for use with a variety of fuse types, including:

- Current-sensing fuse wire - Protects equipment based on electrical current.

- Dual-sensing fuse wire - Provides additional protection by responding to both current and temperature changes.

- Dual-element fuse wire - Designed for long-lasting protection and efficient operation under both overload and short-circuit conditions.

- ELSP current-limiting backup fuse - A fuse that limits current flow to prevent transformer damage during short circuits.

These fuses, in combination with the Bay-O-Net assembly, offer a robust protection system that adapts to changing electrical conditions, ensuring the safety and reliability of high-voltage equipment.

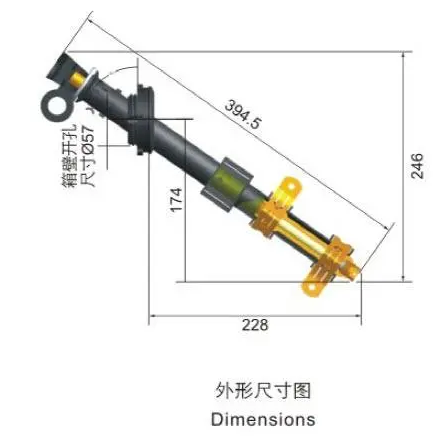

Key Components of the Bay-O-Net Assembly

The Bay-O-Net assembly consists of several key components that work together to provide reliable fuse protection:

- Fuse holder - Houses the fuse and provides a secure connection to the electrical system.

- Bayonet mechanism - Ensures a tight, stable connection between the fuse and the holder.

- Oil-immersed design - The assembly is typically used in oil-filled transformers, where the oil acts as both a coolant and an insulator, helping to regulate temperature and reduce wear on the fuse.

- Interrupter device - The assembly often works in combination with a Magn X Interrupter or an ELSP current-limiting backup fuse, which helps to break the circuit during high-current or short-circuit conditions.

Working Principle of the Bay-O-Net Assembly

The Bay-O-Net assembly is designed to operate under alternating current (AC) conditions, with a frequency of 50 Hz, a standard voltage of 15.5 kV, and a current rating of 140 A.

Here's how it works:

- Overcurrent detection: The Bay-O-Net assembly is connected to the transformer, and when an overcurrent occurs (due to an overload or short circuit), the fuse wire inside the assembly heats up as the current exceeds the rated capacity.

- Current and temperature sensing: Depending on the type of fuse wire used (current sensing, dual sensing, or dual element), the assembly detects both current overloads and oil temperature changes in the transformer. The oil temperature is crucial because it affects the performance of the transformer, and overheating can lead to serious damage.

- Interruption: When a dangerous condition is detected, the fuse wire melts or opens, interrupting the current flow. In cases where the assembly is combined with a Magn X Interrupter or ELSP current-limiting backup fuse, the interrupter device helps to safely disconnect the electrical circuit, protecting the transformer from further damage.

- Safe maintenance and replacement: The bayonet mechanism makes it easy to remove and replace the fuse without the need for specialized tools, reducing downtime and making routine maintenance safer and more efficient.

Applications of the Bay-O-Net Assembly

The Bay-O-Net assembly is widely used in high-voltage power systems, particularly in oil-filled transformers. These transformers are commonly found in utility substations, industrial power distribution systems, and other critical infrastructure that requires reliable power delivery.

Some common applications include:

- Power distribution transformers: Protects transformers from overcurrent and short circuits, ensuring continuous and safe power delivery.

- Industrial equipment: Safeguards high-voltage equipment used in manufacturing and processing plants.

- Renewable energy systems: Used in wind turbines and solar power systems, where transformers play a key role in power conversion and distribution.

In each of these applications, the Bay-O-Net assembly provides reliable, adaptable protection that responds to both current and temperature changes, ensuring the longevity and safety of high-voltage equipment.

Importance of Using Bayonet Fuse Holders in High-Voltage Power Systems

High-voltage power systems are vulnerable to various electrical faults, including overcurrent and short circuits. The use of bayonet fuse holders and Bay-O-Net assemblies is critical for several reasons:

- Protection against overload and short circuits: The primary purpose of these fuse holders is to prevent damage to transformers and other high-voltage equipment by interrupting excessive current flow.

- Temperature-based protection: The Bay-O-Net assembly provides additional protection by responding to changes in oil temperature, ensuring that transformers do not overheat and suffer damage.

- Safe and easy maintenance: The bayonet design allows for quick and safe fuse replacement, minimizing downtime and reducing the risk of accidents during maintenance operations.

- Versatility: These assemblies are compatible with a wide range of fuse types, including current-sensing, dual-sensing, dual-element, and current-limiting backup fuses, making them suitable for various high-voltage applications.

- Efficiency: By providing protection based on both current and temperature, Bay-O-Net assemblies offer highly efficient and responsive protection for critical electrical systems.

Conclusion

The bayonet fuse holder and Bay-O-Net assembly are indispensable components in high-voltage power systems, offering a high level of protection and reliability. By safeguarding transformers and other equipment from overcurrent and overheating, these devices help to maintain the efficiency and safety of electrical infrastructure.

The versatility of the Bay-O-Net assembly, combined with its ability to work with various fuse types, ensures that it remains a critical element in power distribution and industrial applications. For any high-voltage system requiring reliable overload and short-circuit protection, the Bay-O-Net assembly is a proven and effective solution.

Media Contact

Company Name: Anhuang Electric Power Technology Co., Ltd.

Email:Send Email

Country: China

Website: https://www.ahelek.com/