Generally speaking, logistics has three basic links: storage, transportation, and sorting. In the access process, there are two commonly used methods: pallet access and bin access. Previously, tray access was more commonly used, but with the rise of e-commerce and new retail, B2b and B2C businesses have grown rapidly, and the trend of order fragmentation is evident. There is an increasingly widespread demand for access to smaller units such as bins. Meanwhile, compared to traditional warehouses, modern warehousing not only emphasizes the management of space utilization, but also emphasizes the management of time efficiency. Hebei Woke has developed a complete set of intelligent three-dimensional warehousing system solutions based on the characteristics of the modern warehousing and logistics industry, including shuttle vehicle equipment system, high-speed elevator equipment system, cargo to person picking system, conveying system, WCS system, and a four-way shuttle vehicle vertical warehouse integration solution, used to cope with the intelligent operation applications of warehousing, storage, sorting, transportation, and other components in complex production scenarios.

Since Hebei Woke entered the domestic and international markets, its core product HEGERLS four-way shuttle business has successfully partnered with major logistics integrators. Hebei Woke has collaborated with well-known domestic and foreign brands such as cross-border e-commerce, shoe and clothing e-commerce, and 3C Electronics to provide one-stop intelligent logistics services such as products, technology, and after-sales service. The cases are widely used in more than 20 sub industries, such as medicine, automobile, retail, e-commerce, library, rail transit, sports, manufacturing and third-party logistics, and a total of more than large and medium-sized modern logistics centers and production oriented three-dimensional warehouses have been built.

Line logistics field

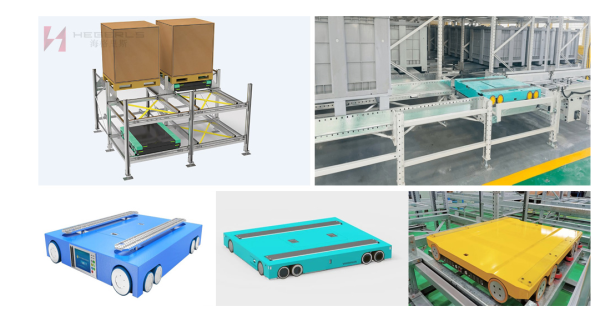

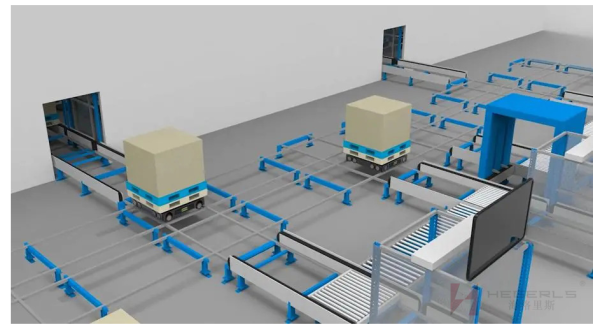

With the upgrading of intelligent manufacturing at home and abroad, as well as the rapid development of industrial processes, factory line side warehouses and in factory logistics play an important role in achieving intelligent manufacturing in enterprises, and line side logistics is precisely the applicable field of the four-way shuttle system. The HEGERLS four-way shuttle is more flexible and can travel along longitudinal or transverse tracks on the intersecting tracks of three-dimensional shelves. It can reach any designated storage location in the warehouse through instructions issued by the system. At the same time, the HEGERLS four-way shuttle can fully utilize the lower space of the production workshop roof, combine with the elevator to complete material transportation, and avoid crossing with ground logistics lines. However, due to the greater difficulty in planning the logistics system in the manufacturing industry, it is necessary to closely align the logistics with the process flow and match it with the entire production system. Therefore, it takes more time to refine the plan and the project implementation cycle is longer.

Medical circulation field

In recent years, the field of medical circulation has faced increasing challenges. Compared with other conventional industries, the pharmaceutical industry has tens of thousands of varieties, multiple batch numbers, and high logistics sorting complexity, which have extremely high requirements for the automation level, processing efficiency, reliability, safety, and other aspects of its system. The HEGERLS four-way shuttle will be arranged according to different SKUs and cargo locations, and the algorithm will automatically recommend suitable cargo locations when goods enter the warehouse, allowing goods to be stored according to certain rules and avoiding congestion during later outbound operations, improving efficiency; When leaving the warehouse, the algorithm also recommends the optimal storage location, and calculates various factors such as distance, hindrance to tasks, and final inventory to provide the optimal storage location; It can also achieve inventory visualization and easily view the status of any storage location through a graphical interface, with strong adaptability, high reliability, strong scalability, and high flexibility. In the future, Hebei Woke will continue to provide more comprehensive solutions for customers in different industries.

Dismantling and picking industry

The HEGERLS four-way shuttle system is also very suitable for dismantling and picking in industries such as cosmetics. It is like a fruit picking system, where a HEGERLS four-way shuttle is equivalent to a picking worker, who can complete the picking of one or more order lines in one operation cycle. Its speed is faster, reaching 2M/S, which is 5 times the efficiency of manual picking operations; At the same time, with the help of precise positioning technology, it can also save time in finding cargo spaces; The picking action is also faster. So overall, a HEGERLS four-way shuttle can achieve a picking workload of 2-3 workers per shift. If calculated as two shifts per 24 hours, it can replace 4-6 workers, undoubtedly having more advantages in terms of economy.

In terms of product stability, rich application scenarios, and brand awareness, Hebei Woke has rapidly grown into a leading logistics robot intelligent equipment supplier and technical service provider, providing high-quality and highly intelligent robot solutions to more domestic and foreign customers.

Original Source: https://www.wkrack.com/news/logistics-intelligent-handling-robot-intelligent-operation-application-of-hegerls-four-way-shuttle-in-complex-production-scenarios/

Media Contact

Company Name: Hebei Woke Metal Products Co., Ltd.

Email:Send Email

Address:Room 1118, Building No.6, Tatan Mall, Tatong Street, Production base: 68 Shidai Road, Xinhe Industrial Park

City: Shijiazhuang

State: Hebei

Country: China

Website: https://www.wkrack.com/