Power supply design is very important. It greatly affects the performance and cost of the entire system. Most people's concept of capacitance still has a superficial meaning. People don't know the difference between a 1uF ceramic capacitor and a 1uF aluminum capacitor. This article introduces the use of capacitors in circuit board power supply design.

First, we introduce several important parameters of capacitance.

C: Capacitance value. Generally, it is measured at 1kHz, 1V equivalent AC voltage, and DC bias voltage of 0V. However, there can be many different environments for capacitance measurement. The capacitance value C itself will change with the environment.

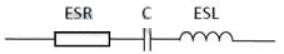

ESL: Capacitor equivalent series inductance. The pins of the capacitor are inductance. We need to consider it in the case of higher frequency.

ESR: Capacitor equivalent series resistance. No matter what kind of capacitor will have an equivalent series resistance, when the capacitor works at the resonance frequency, the capacitance and inductance of the capacitor are equal. Thus, a resistance ESR is equivalently formed. The ESR of aluminum capacitors generally ranges from a few hundred milliohms to a few ohms. Ceramic capacitors are generally tens of milliohms. Tantalum capacitors are between aluminum capacitors and ceramic capacitors.

Now introduce the three types of capacitors we commonly use: aluminum capacitors, ceramic capacitors and tantalum capacitors.

Aluminum Capacitor

Aluminum capacitors are made by oxidizing the aluminum foil and then sandwiching an insulating layer, and then immersing it in electrolyte. Capacitor charging and discharging rely on chemical reactions. The response speed of the capacitor to the signal is limited by the moving speed of the charged ions in the electrolyte. It is generally used in filtering occasions with low frequency (below 1M). ESR is the sum of the resistance of the aluminum foil and the equivalent resistance of the electrolyte. Usually its resistance is relatively large. The electrolyte of aluminum capacitors will gradually volatilize. It causes the capacitance to decrease or disappear. As the temperature increases, its volatilization rate will be faster. The lifetime of the capacitor will be halved for every 10 degree increase in temperature. Therefore, the aluminum capacitor should not be too close to the heat source.

Ceramic Capacitor

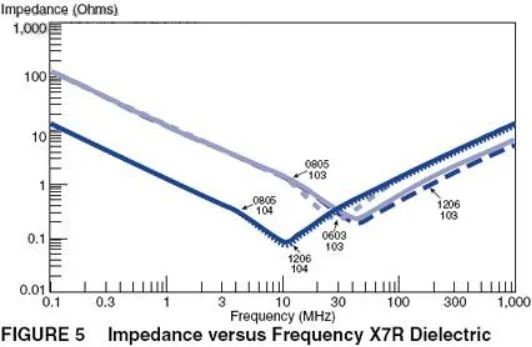

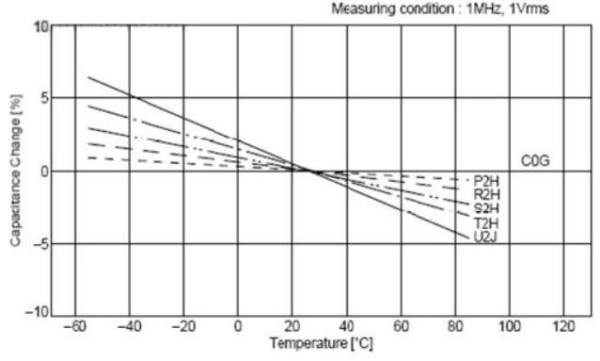

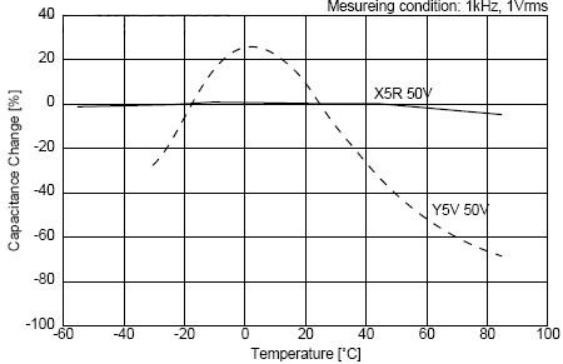

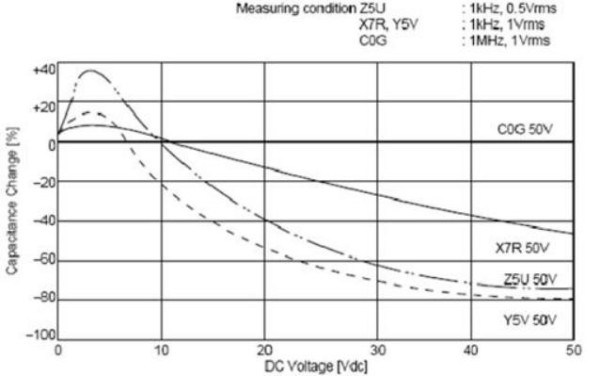

Ceramic capacitors rely on physical reactions to store electricity, so they have a very high response speed. Ceramic capacitors also show great differences due to different dielectrics. The best performance is the capacitor made of C0G. Its temperature coefficient is small. However, its material has a small dielectric constant, so its capacitance value is not large. The worst performance is the Z5U/Y5V material. Its dielectric constant is large, so the capacitance can reach tens of microfarads. However, this material is greatly affected by temperature and DC bias. Now let's take a look at the state of the three material capacitors of C0G, X5R, and Y5V affected by the ambient temperature and DC working voltage.

When the temperature changes, the capacitance of C0G is not affected. X5R is not stable. At 60 degrees, the capacity of Y5V material becomes 50% of the nominal value.

When used at 30V, the capacity of the 50V Y5V ceramic capacitor is 30% of the nominal value. Ceramic capacitors have a big disadvantage, that is, they are fragile. Therefore, it is necessary to avoid bumps and try to stay away from the place where the circuit board is prone to deformation.

Tantalum Capacitor

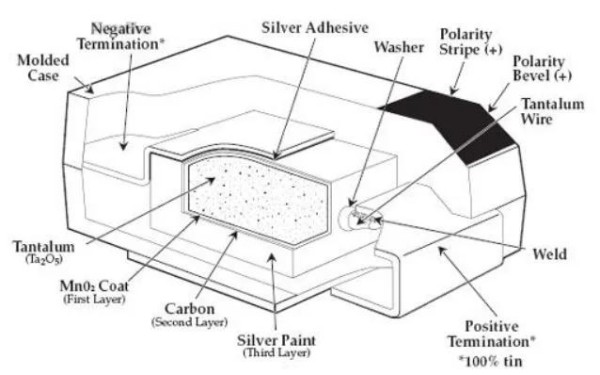

Tantalum capacitors are like a battery in principle and structure. The following is a schematic diagram of the internal structure of a tantalum capacitor:

Tantalum capacitors have the advantages of small size, large capacity, fast speed, low ESR, etc., and the price is relatively high. What determines the capacity and withstand voltage of tantalum capacitors is the size of the raw material tantalum powder particles. The finer the particles, the larger the capacitance, and if one wants to get a larger withstand voltage, he/she needs thicker Ta2O5, which requires the use of larger particles of tantalum powder. Therefore, it is very difficult to obtain tantalum capacitors with high withstand voltage and large capacity for the same volume. Another point that tantalum capacitors need to pay attention to is that tantalum capacitors are relatively easy to break down and exhibit short-circuit characteristics, and their anti-surge capability is poor. A large instantaneous current may cause the capacitor to burn out and form a short circuit. Therefore, one needs to consider this factor when using ultra-large-capacity tantalum capacitors.

Conclusion From this article, people can learn that different capacitors have different applications. The higher the price of the capacitor is not necessarily the better. Welcome to easybom to search for more content.

Fcebook link: https://www.facebook.com/easybom.electronic

Twitter link: https://twitter.com/easybom_tech

Linkedin link: https://www.linkedin.com/company/easybom

Media Contact

Company Name: EASYBOM, INC.

Contact Person: Media Relations

Email:Send Email

Phone: 718-737-2822

City: SEATTLE

State: WA

Country: United States

Website: https://www.easybom.com