1. The development background of microtubule and microcable technology

After the emergence of the new technology of microtubule and microcable, it has become popular. Especially the European and American markets. In the past, direct-buried optical cables could only be constructed repeatedly one trunk line by trunk line, but when the pipeline appeared, the optical cable upgrade could be realized by pre-buried empty pipes. Nowadays, the construction method of air-blown optical fiber cable has been adopted in many trunk optical cable projects in our country. In the United States, Germany, France, the Netherlands, Denmark and other countries, the application of air-blown optical fiber cable laying technology has been very common. Needless to say, the advantages of this investment construction method and the optical cable laying method, but the disadvantage of this construction method is that only one optical cable can be blown in a plastic tube (generally 40/33mm in diameter), and the cable diameter is not divided. The thickness and number of cores. The microtube and microcable technology solves this problem.

2. Microtube and microcable technology and its products

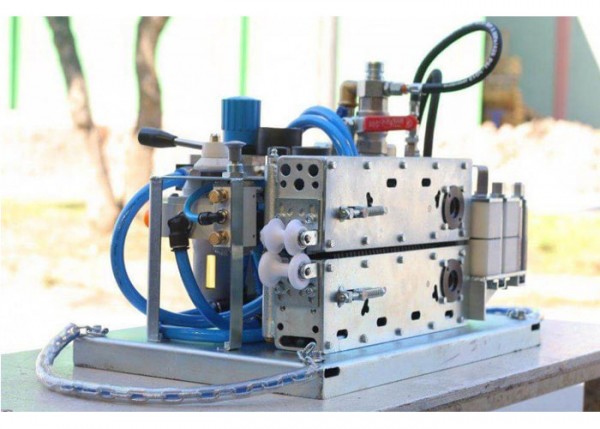

The so-called micro-cable usually refers to each miniature optical cable product containing 12 to 96-core optical fibers. The cable diameter is much smaller than that of ordinary optical cables. At present, the market tends to adopt stainless steel tube and central bundle tube structure. The so-called micro-pipe is to lay HDPE or PVC plastic pipes in advance, called the mother pipe, and then blow the HDPE sub-tube bundles into the mother pipe with airflow, so that the micro-optical cables can be conveniently laid in batches in the future. When the optical cable is constructed, the high-speed compressed air produced by the air compressor and the micro optical cable are sent into the sub-pipe by the air blower.

3. The main advantages of microtubule and microcable technology

Compared with the traditional direct buried and pipeline laying methods, the main advantages of the microtubule and microcable laying technology are as follows

(1) Make full use of limited pipeline resources to realize "one tube with multiple cables". For example, a 40/33 tube can accommodate 5 10mm or 10 7mm microtubes, and a 10mm microtube can accommodate 60-core micro-cables, so a 40/33 tube can accommodate 300-core optical fibers In this way, the laying density of the optical fiber is increased, and the utilization rate of the pipeline is improved.

(2) Reduced initial investment. Operators can blow in micro-cables in batches and invest in installments according to market demand.

(3) The micro-tube and micro-cable provide greater flexible capacity expansion, which greatly meets the sudden demand for optical fiber in urban broadband services.

(4) Easy to construct. The air blowing speed is fast and the one-time air blowing distance is long, which greatly shortens the construction period. Because the steel pipe has certain rigidity and elasticity, it is easy to push in the pipe, and the longest blow-in length can be more than 2km.

(5) The optical cable is stored in the microtube for a long time, and is not corroded by water and moisture, which can ensure the working life of the optical cable for more than 30 years.

(6) Facilitate the addition of new varieties of optical fibers in the future, keep ahead in technology, and continue to adapt to market needs.

While the telecommunications network continues to develop, new requirements are constantly being placed on optical cable products. The structure of the optical cable increasingly depends on the environment of use and the specific requirements of construction. In the future, the focus of optical cable construction will continue with the construction of access networks and customer premises networks, and there will also be a series of new changes in the new generation of optical cable structure and construction technology. Microtube and microcable technology will be widely used in the construction of metropolitan area networks, access networks, and other expansion projects in the future.

Media Contact

Company Name: Guang Lian

Contact Person: Media Relations

Email:Send Email

Phone: +86 7318 9722704

Country: China

Website: https://www.gl-fiber.com/