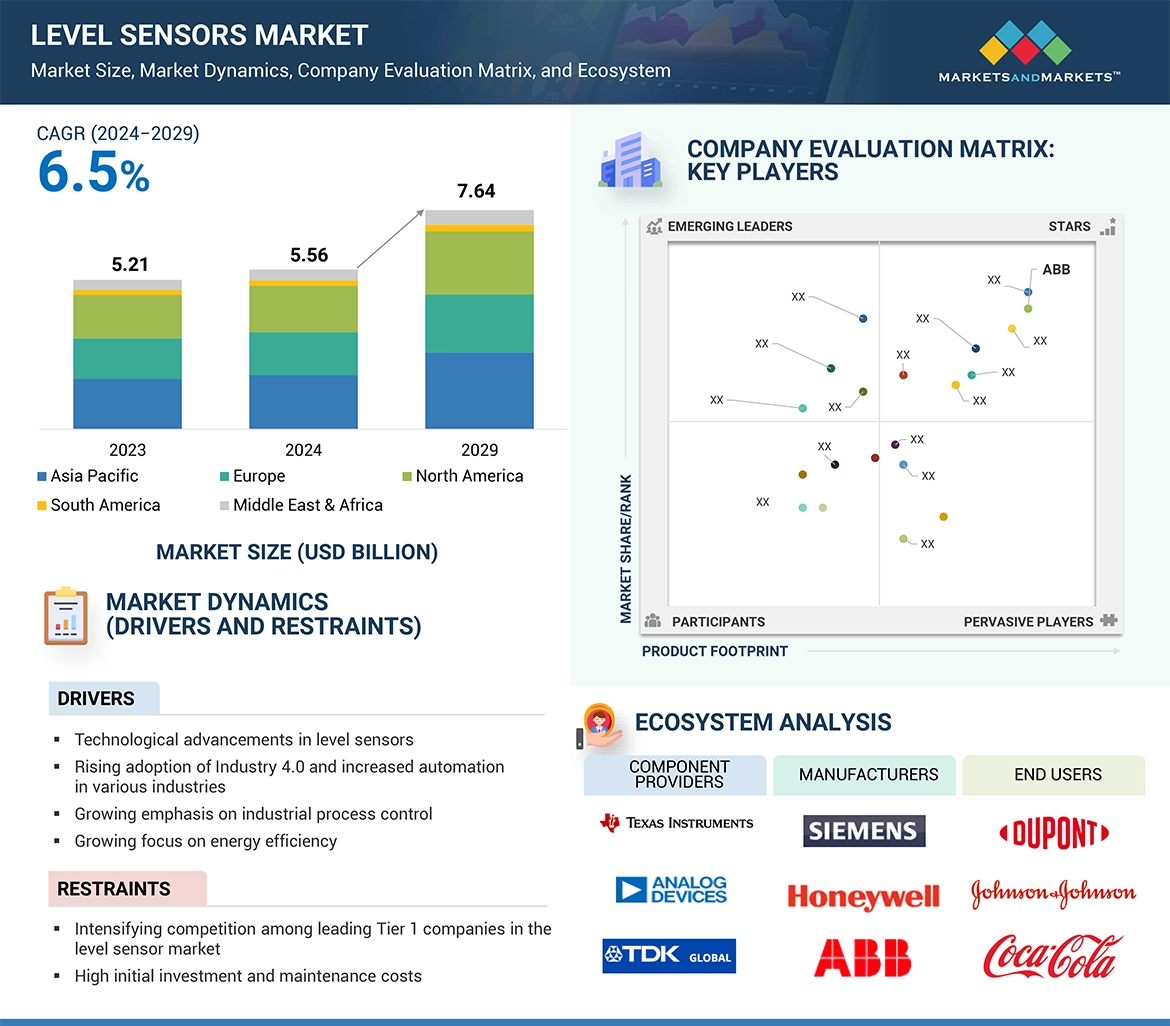

The report "Level Sensor Market by Type (Magnetostrictive, Vibratory Probe, Hydrostatic, Magnetic & Mechanical Float, Pneumatic, Guided Wave, Ultrasonic, Microwave, Optical, Capacitance Level Sensors), Sensor Type (Contact, Non-contact) - Global Forecast to 2029" The global level sensors industry size is projected to reach USD 7.64 billion in 2029 from USD 5.56 billion in 2024, with a CAGR of 6.5%.

Level sensor market growth is mainly fueled by the increasing demand for accurate and reliable level measurements in several manufacturing-related industries, as well as oil and gas, chemicals, and food and beverages. In addition, the growing adoption of automation, and initiatives under Industry 4.0, accompanied by increased demand for improved process efficiency and safety, will further drive the demand for advanced-level sensing technologies. With the mounting focus on environmental monitoring and sustainability, industries are adopting advanced-level sensors for resource management and environmental compliance.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=926

Browse 160 market data Tables and 60 Figures spread through 285 Pages and in-depth TOC on "Level Sensor Industry"

View detailed Table of Content here - https://www.marketsandmarkets.com/Market-Reports/level-sensors-market-926.html

Contact level sensors are projected to maintain a significant CAGR in the global level sensor industry during the forecast period.

Contact level sensors is expected to account for a significant growth rate in the global level sensor industry during the entire forecast period. This is due to their efficiencies in many industrial applications. Such sensors operate by directly making contact with the liquid or solid to be measured, to achieve precise measurements of levels, leaks, and flow rates. Their reliability, cost-effectiveness, and ability to function well in challenging environments like high temperatures or pressures make them perfect fits for industries like oil & gas, water & wastewater, and chemicals. Even though non-contact alternatives are increasing in popularity, contact sensors are still preferred due to the proven track record of performance at achieving accurate and uninterrupted level monitoring in the application.

Magnetic and Mechanical Float level sensors are expected to capture a significant share in the global market during the forecast period.

Magnetic and mechanical float level sensors are expected to capture a significant share of the market during the forecast period. These sensors work on float principle, where the float rises or falls with the liquid level, thus triggering a magnetic or mechanical switch indicating the level. It is ideal for those water & wastewater, oil & gas, and chemical processing industrial applications where very accurate monitoring of level is necessary. Its rugged design and the ability to operate well under harsh environments also support continued demand in many diverse applications. The high growth rate of automation will also boost the need for such proven technologies.

Continuous level monitoring is projected to hold the largest share in the global level sensor industry during the forecast period.

During the forecast period, continuous level monitoring will maintain the largest share in the level sensor industry since it can offer real-time, accurate measurement of liquid or solid levels over a long range. In contrast to point level sensors, which report only at a specific threshold being achieved, continuous level sensors track the entire range of levels. Continuous level sensors are more useful where precise level maintenance is absolutely necessary like in applications involving chemical processing, water treatment, or food production. Their ability to provide real time updates increases operational efficiencies, reduces downtime, and supports automated systems that require constant feedback about the material level. With the rising adoption of automation and smart manufacturing, the demand for this solution is expected to increase dramatically and that would further cement its position as a critical segment of the level sensor industry.

Liquid level sensors are projected to capture the highest share in the global level sensor industry during the forecast period.

By application liquid level sensors are projected to capture the highest share of the level sensor industry. Liquid applications require precise monitoring of liquid levels for both safety and process efficiency reasons and to ensure compliance with regulatory procedures. For example, reliable liquid-level sensors enable consistent product quality in food production and ensure optimal levels of water inside a wastewater plant. Advancements in wireless communication and further integration with IoT have been adding to the development of liquid level monitoring. The demand for liquid-level sensors is likely to grow in the coming years, driven by increasing automation and real-time analytics.

The pharmaceuticals sector is expected to experience significant growth in the level sensor industry during the forecast period.

The pharmaceutical industry is expected to grow at a significant CAGR in the level sensor industry over the forecast period. There is an increasing demand for the measurement of levels during critical processes such as drug formulation, fluids, and chemical storage. Level sensors play an extremely significant role in the pharmaceutical environment to ensure safety and compliance with strict regulatory standards to ensure that the product is of high quality. Implementation of automation and in-line monitoring will highly contribute to increased operational efficiency and reduced risks of contamination, thus increasing the demand for higher-grade sensors. Also, pharmaceutical production will further benefit from IoT and smart manufacturing technologies through improvement in the growth of level sensors.

Asia Pacific to capture the highest share in the global level sensor industry during the forecast period.

The Asia-Pacific region is expected to lead the level sensors industry during the forecast period. The tremendous growth is catalyzed by rapid industrialization, positive influences in manufacturing activities, and on-ground adoption of automation technologies across various process industries. In this region, industries like automotive, pharmaceuticals, chemicals, and water & wastewater management have expanded levels of dependency on precise level monitoring to enhance operational efficiency and meet standards defined by regulations. Besides, smart manufacturing and the support of IoT will increase the adoption of level sensors. As industrial automation and infrastructure investment is picking up demand for level sensors, in Asia Pacific, is likely to be increase.

Major companies operating in the level sensors industry include ABB (Switzerland), Emerson Electric Co. (US), AMETEK.Inc. (US), Siemens (Germany), and Honeywell International Inc. (US).

Media Contact

Company Name: MarketsandMarkets™ Research Private Ltd.

Contact Person: Mr. Rohan Salgarkar

Email:Send Email

Phone: 18886006441

Address:1615 South Congress Ave. Suite 103

City: Delray Beach

State: FL 33445

Country: United States

Website: https://www.marketsandmarkets.com/Market-Reports/level-sensors-market-926.html