Empowering India’s Green Energy Revolution: Comwin Group Delivers the World’s Best Battery Pack Assembly Solutions

In a landmark move that underscores its global leadership in new energy equipment, Shenzhen Comwin Intelligent Equipment Group (Comwin Group) has successfully exported its state-of-the-art Battery Pack Assembly Lines and comprehensive battery manufacturing equipment to India. As a national-level high-tech enterprise with over a decade of expertise in prismatic cell modules and complete PACK solutions, Comwin is now bringing its unparalleled technology to one of the world’s fastest-growing markets for electric vehicles (EVs) and renewable energy storage. This export not only highlights Comwin’s commitment to international collaboration but also positions India at the forefront of sustainable energy production with equipment that is widely regarded as the best in the industry.

Why Comwin’s Battery Pack Assembly Lines and Manufacturing Equipment Stand Out as the BestComwin Group’s offerings are engineered for superior performance, reliability, and adaptability, making them the top choice for manufacturers worldwide. Tailored specifically for the Indian market’s diverse needs—from bustling urban EV fleets to expansive solar energy storage projects—these assembly lines and equipment deliver unmatched efficiency, precision, and scalability. Here’s a closer look at what sets them apart:

-

Unrivaled Automation and Efficiency: Comwin’s Battery Pack Assembly Lines boast a high degree of automation, achieving efficiencies of 12-30 PPM (modules/PACK per minute). Utilizing intelligent robots, machine vision inspection, and automated feeding systems, they minimize manual intervention, reduce errors, and boost overall equipment effectiveness (OEE) to over 98%. In India, where labor costs and production scalability are key concerns, this translates to faster turnaround times and lower operational expenses—making Comwin’s solutions the gold standard for high-volume manufacturing.

-

Advanced Laser Welding and Quality Assurance: At the heart of Comwin’s equipment is cutting-edge laser welding technology for busbar, side seam, and module connections, ensuring rock-solid stability and safety. Integrated End-of-Line (EOL) testing, including helium leak detection and electrical performance checks, guarantees yield rates exceeding 99.9%. No other manufacturer matches this level of precision (±0.2mm repeatability), which is crucial for India’s growing demand for safe, durable batteries in EVs and grid storage.

-

Flexibility and Customization for Indian Needs: Comwin excels in modular design, allowing quick model changes and non-standard customizations based on specific cell processes. Whether it’s lithium iron phosphate, ternary lithium, or sodium-ion batteries, these lines support multiple specifications with servo fixtures and tray quick-change systems. For Indian clients, this means seamless adaptation to local regulations, varying battery sizes, and emerging applications like two-wheelers, three-wheelers, and rural energy storage—proving why Comwin is the preferred partner for customized excellence.

-

Intelligent Digital Management: Powered by MES (Manufacturing Execution System) and digital twin technology, Comwin’s equipment enables real-time data monitoring, traceability, and predictive maintenance. This digital edge not only optimizes production but also supports India’s “Make in India” initiative by enhancing local manufacturing capabilities with smart, eco-friendly processes that meet global environmental standards.

Technical Insights: Demystifying Comwin’s Battery Manufacturing EquipmentTo appreciate why Comwin’s exports to India are a game-changer, let’s dive into the core technologies:

-

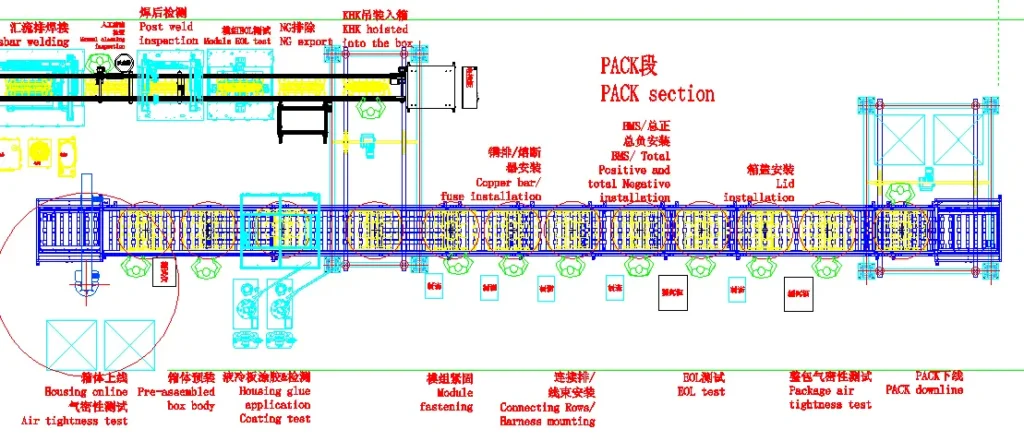

Prismatic Battery Pack Assembly Process Flow: From cell feeding and OCV testing to adhesive application, stacking, busbar welding, EOL testing, and airtightness checks, the entire workflow is streamlined for maximum throughput. This end-to-end automation ensures consistency, making it ideal for India’s high-demand sectors.

-

Key Parameters of Excellence: Equipment dimensions (80,000x1,000x3,500mm) fit compactly into facilities (occupying just 800m²), with a power draw of 150kW and failure rates under 1%. These specs deliver the highest utilization rates and reliability, outperforming competitors in cost-effectiveness and longevity.

-

Environmental and Safety Focus: Comwin’s designs prioritize sustainability, with low-energy operations and compliance with international standards, aligning perfectly with India’s push towards green manufacturing.

Transforming India’s Energy Landscape with Superior ApplicationsComwin’s Battery Pack Assembly Lines and manufacturing equipment are already powering diverse applications in India:

- Electric Mobility: From EVs and electric rickshaws to golf carts and automated guided vehicles, Comwin ensures high-energy-density packs that extend range and reliability.

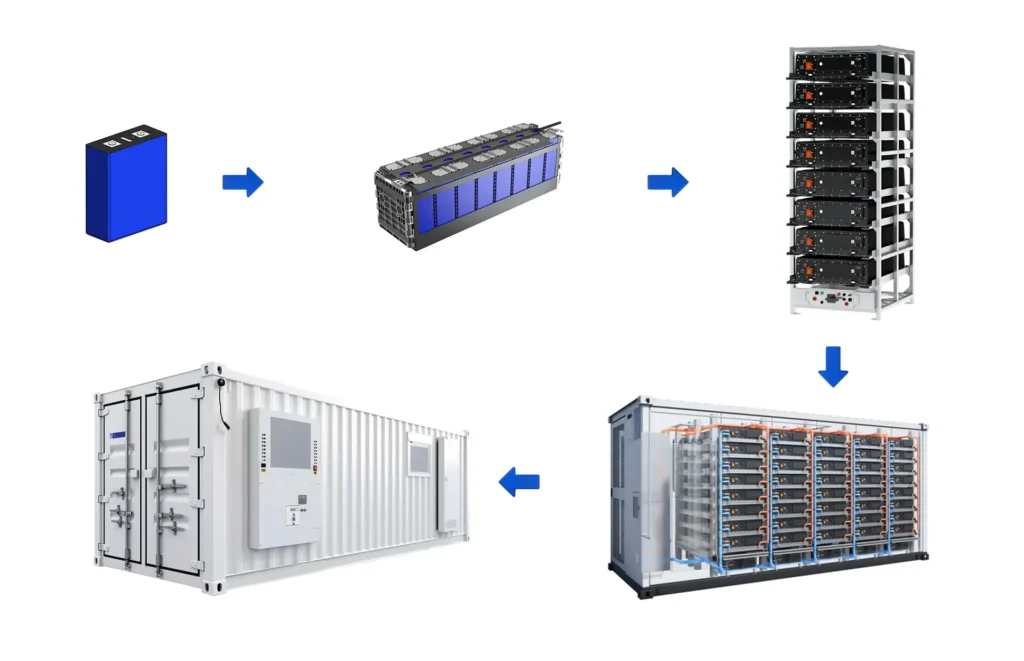

- Energy Storage Solutions: Supporting home energy systems, communication base stations, containerized storage, and even satellite power systems, these lines enable scalable, resilient storage for India’s renewable energy goals.

- Specialized Sectors: Ideal for electric boats, firefighting robots, unmanned submersibles, and medical ventilators, where precision and durability are non-negotiable.

By choosing Comwin, Indian manufacturers gain a competitive edge, reducing dependency on imports and fostering local innovation. Clients report up to 30% improvements in production efficiency and significant cost savings, solidifying Comwin’s reputation as the best in the business.

Comwin Group’s Global Vision and R&D StrengthWith a dedicated R&D team of over 200 experts, Comwin has mastered the full spectrum of new energy equipment—from cell processing to finished PACKs. This export to India is a testament to the company’s global outreach, having served clients in Europe, North America, and Asia. Comwin’s focus on innovation ensures that its equipment not only meets but exceeds industry benchmarks, helping partners like those in India achieve sustainable growth.

Join the Revolution: Partner with Comwin for Unmatched QualityAs India accelerates its transition to clean energy, Comwin Group’s exported Battery Pack Assembly Lines and manufacturing equipment offer the ultimate solution—reliable, efficient, and future-proof. Contact Comwin’s international team today to explore customized options, detailed case studies, and how these best-in-class systems can elevate your operations. Together, let’s build a brighter, greener future for India and beyond.

Conclusion

Comwin Group’s entry into the Indian market with its premier Battery Pack Assembly Lines and battery manufacturing equipment marks a new era of excellence. Renowned for superior technology, customization, and performance, Comwin is not just exporting equipment—it’s exporting success. Choose Comwin, and experience why it’s universally acclaimed as the best choice for advancing India’s energy ambitions.

Media Contact

Company Name: Shenzhen Comwin Intelligent Equipment Group Co., Ltd.

Contact Person: Key Shaw

Email:Send Email

Phone: 15015614961

Address:Baoan

City: Shenzhen

State: Guangdong

Country: China

Website: https://auto-odm.com/battery-pack-assembly-line-manufacturer/