Introduction

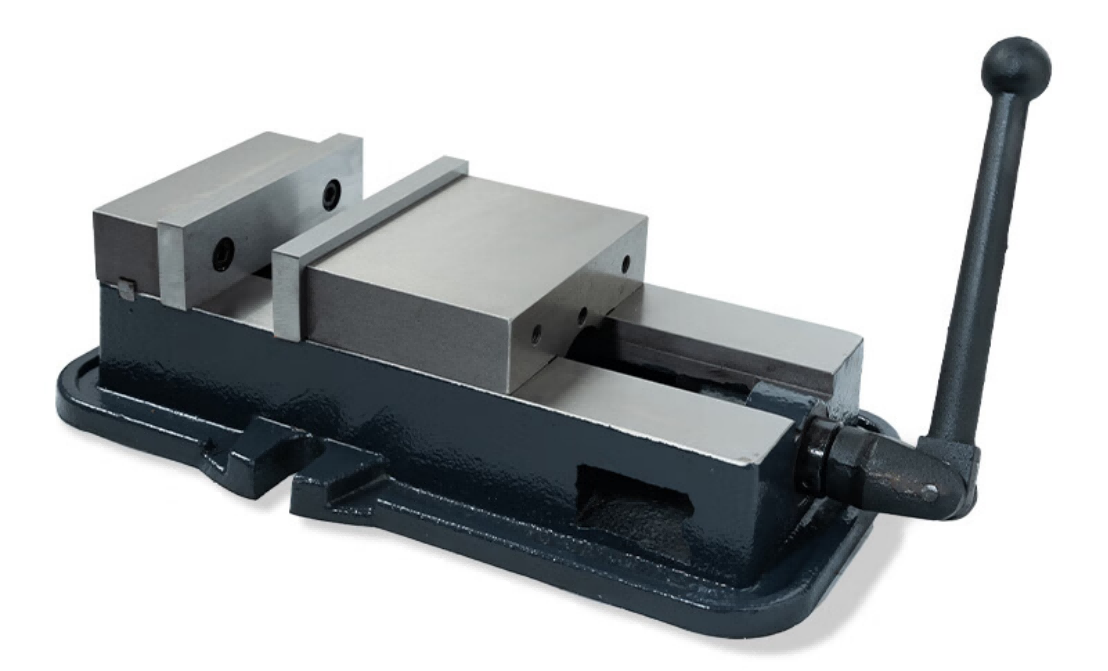

The Machine Vise, also known as a milling vise, is an indispensable auxiliary tool in machining, widely used in milling machines, drilling machines, and surface grinders. It clamps and releases workpieces via a screw drive mechanism, offering simple operation yet powerful functionality. However, many operators often overlook proper installation and maintenance, leading to reduced tool lifespan or compromised machining accuracy. This article provides a detailed guide on correctly installing and maintaining machine vises to extend their service life and ensure machining quality.

alt. CNC Machine Tool Vise

Installation of Machine Vises1. Pre-Installation Preparation

Before installation, ensure the vise base and milling machine table are clean and free of debris. Typically, the vise should be positioned slightly left of the machine table center for ease of operation.

2. Aligning the Fixed Jaw

The fixed jaw must be parallel or perpendicular to the spindle axis. The alignment methods are as follows:

Method 1: Using a Scriber (For Long Workpieces)

- Secure a scriber to the Tool Holder shim, positioning the tip close to the fixed jaw surface.

- Move the table longitudinally and observe the gap between the scriber and the jaw.

- Adjust the vise body until the gap is uniform, then tighten and recheck.

Method 2: Using a Square (For Short Workpieces)

- Loosen the vise body fastening nuts to roughly align the fixed jaw with the spindle axis.

- Place a square against the machine’s vertical guideway and adjust the vise until the jaw fits snugly.

- Tighten the vise and verify alignment.

Method 3: Using a Dial Indicator (For High-Precision Machining)

- Attach a magnetic base to the cross rail or guideway and mount a dial indicator.

- Adjust the probe to be perpendicular to the jaw surface with 0.3–0.4mm compression.

- Move the table and check readings to ensure consistency along the jaw’s length before tightening.

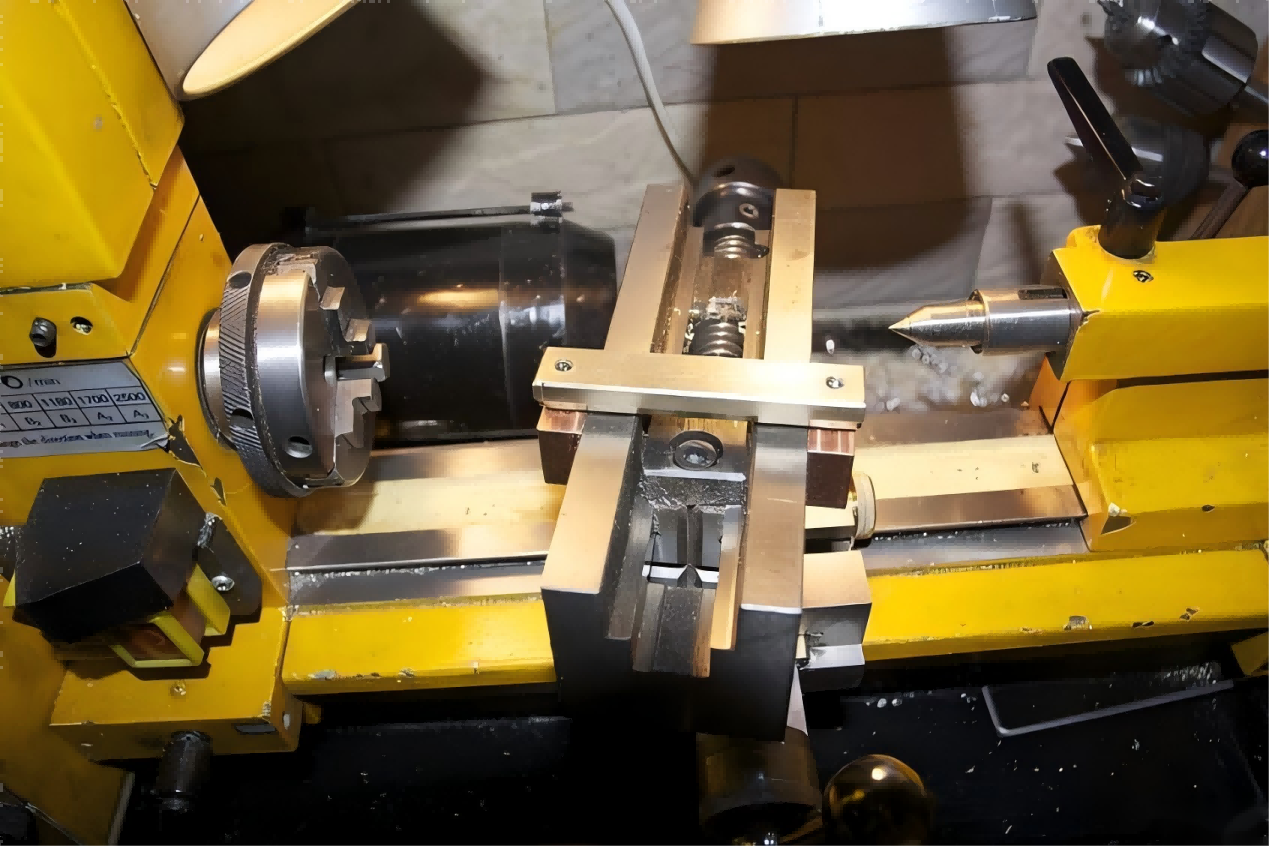

alt. CNC Machine Vise Installation

Routine Maintenance of Machine Vises

Proper maintenance significantly extends a vise’s lifespan. Key practices include:

- Pre-Use Cleaning: Always clean the vise base and machine table before use to remove chips or oil.

- Correct Installation: Align the keyway with the table’s T-slot and lightly secure the screws (default groove: 18mm).

- Regular Oil Checks: Inspect Hydraulic Cylinder oil levels at least every 6 months. Use No. 140 or equivalent oil, avoiding air ingress.

- Avoid Forceful Handling: Never strike the handle with a hammer to prevent structural deformation.

- Control Jaw Opening: Avoid overextending the jaws to protect the screw and jaw integrity.

- Calibration Checks: Periodically verify the fixed jaw’sperpendicularity/parallelism to maintain accuracy.

Conclusion

Though small, machine vises play a vital role in machining. Proper installation and regular maintenance not only enhance precision but also prolong their service life. By following the alignment and care techniques outlined here, you can use your vise more efficiently and safely, boosting productivity!

Media Contact

Company Name: Qingdao Micro Precision Machinery Co., Ltd.

Email:Send Email

Phone: +86-15589891818

Address:No. 438, Wangsha Road, Chengyang District

State: Qingdao

Country: China

Website: https://www.mpmmachine.com/