Industry Challenge: EVA’s Wear Resistance Problem

EVA (ethylene-vinyl acetate) has become the backbone of modern footwear thanks to its lightweight comfort, excellent cushioning, and flexibility. From midsoles to outsoles, EVA provides a smooth wearing experience.

Yet for manufacturers, one critical challenge persists: low abrasion resistance. Unlike rubber or TPU, EVA soles can wear down quickly, leading to:

1. Shorter product lifespan – Shoes lose grip and cushioning faster.

2. Higher replacement and warranty costs – Brand reputation may suffer.

3. Consumer dissatisfaction – Especially in sports and performance shoes, where durability is a must.

This raises a question for footwear brands: How can EVA maintain its softness while achieving long-lasting abrasion resistance?

Common approaches to improve wear resistance in EVA shoe soles

Footwear material engineers have traditionally adopted several solutions:

Fillers (Silica & Carbon Black): Improve hardness and toughness, but may compromise comfort and increase density.

Nano-fillers (Nano-silica, Nano-clay): Offer reinforcement at the molecular level, but often face challenges in dispersion and processing cost.

Rubber blending: Enhances durability but reduces EVA’s lightweight advantage.

While these methods provide partial improvements, they often require trade-offs between comfort, weight, and durability.

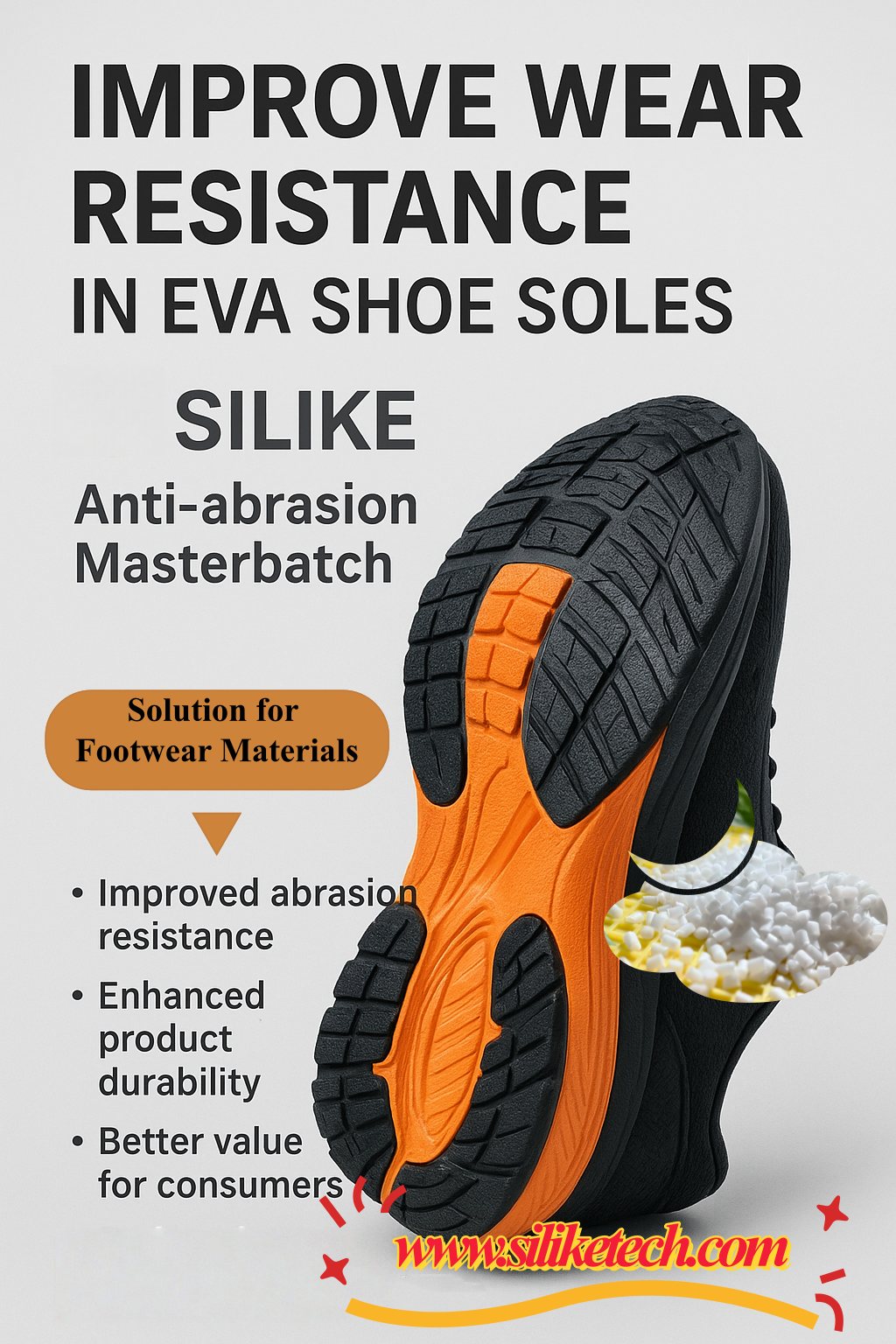

Solution: SILIKE Anti-abrasion silicone masterbatch for EVA shoe sole material

To address these trade-offs, SILIKE developed a specialized Anti-Wear Agent, NM-2T, designed for EVA and EVA-compatible resin systems to enhance abrasion resistance and reduce the abrasion rate in thermoplastic products. Compared to conventional low molecular weight silicone or siloxane additives—such as silicone oils, silicone fluids, Silica, or other types of abrasion modifiers—SILIKE Anti-Abrasion Masterbatch NM-2T delivers superior abrasion resistance without affecting hardness or color. This solution is engineered to improve durability while maintaining softness, aesthetic appeal, and eco-friendliness.

Key Benefits of SILIKE Anti-Abrasion Masterbatch for EVA Shoe Outsoles:

1. Enhanced Wear Resistance: SILIKE Anti-Wear Masterbatch NM-2T meets DIN, ASTM, NBS, AKRON, SATRA, and GB abrasion test standards.

2. No Impact on Comfort: Maintains the original EVA softness and flexibility.

3. Aesthetic Integrity: Does not affect hardness or color, preserving design freedom.

4. Eco-Conscious Choice: Safe, sustainable, and comfortable to wear.

5. Process-Friendly: Improves extrusion and molding performance, ensuring consistent product quality.

SILIKE silicone masterbatch anti-abrasion agents have been trusted and successfully used across diverse footwear manufacturing applications

• Running and basketball shoes: Withstand high-impact sports activities.

• Cheerleading and training shoes: Maintain traction and durability under intensive use.

• Casual and lifestyle footwear: Extend product life while preserving lightweight comfort.

• Professional sports shoes: Balance performance, comfort, and sustainability.

For shoe sole material and footwear manufacturers, these wear-resistant solutions mean fewer abrasion complaints, longer product cycles, and improved consumer satisfaction.

Why is SILIKE a trusted professional supplier of wear-resistant agents for shoe materials? 1. Industry Expertise: Decades of experience in silicone-based polymer additives.

2. Global Footprint: Trusted by footwear brands across Asia, Europe, and North America.

3. Technical Validation: Compliance with major international abrasion test standards.

4. Sustainability Commitment: Developing eco-friendly solutions aligned with consumer and regulatory trends.

Upgrade Your EVA Footwear: Durability, Comfort, and Long-Lasting Wear Resistance.

If your brand is looking to differentiate itself through durability, reduce costs associated with wear-related issues, and improve consumer loyalty, integrating SILIKE Anti-abrasion Masterbatch is the solution.

Please reach out to us to get your silicone-based anti-wear additives solutions!

Call: +86-28-83625089

Email: amy.wang@silike.cn

Learn more: www.siliketech.com

Media Contact

Company Name: Chengdu Silike Technology Co., Ltd.

Email:Send Email

Country: China

Website: https://www.siliketech.com/