In November 2023, UK-based client KURE visited the King Machine factory for the first time. Within just one day, both parties finalized key technical details for a 12,000 bottles per hour (BPH) oxygen-enriched water filling line. King Machine quickly optimized the production layout based on the customer’s real-world requirements, ensuring smooth operation upon deployment. Impressed by King Machine’s professionalism and efficiency, the client arranged the deposit payment immediately after returning to the UK, officially launching the project.

The production line needed to handle two bottle types and two cap types: standard 28mm carbonated beverage caps and sport caps. To meet this challenge, King Machine implemented an innovative “single capper, dual cap feed” solution—using one capping machine with two independent cap feeding systems: a cap elevator for standard plastic caps and a vibratory cap sorter for sport caps—greatly enhancing flexibility and efficiency.

High-Quality Manufacturing Meets International Standards

In June 2024, the customer visited the King Machine factory to conduct the final inspection. The complete line—featuring an automatic 3-in-1 filling machine, rotary labeling machine, handle applicator, case packer, shrink wrapper, and conveyor system—performed flawlessly.

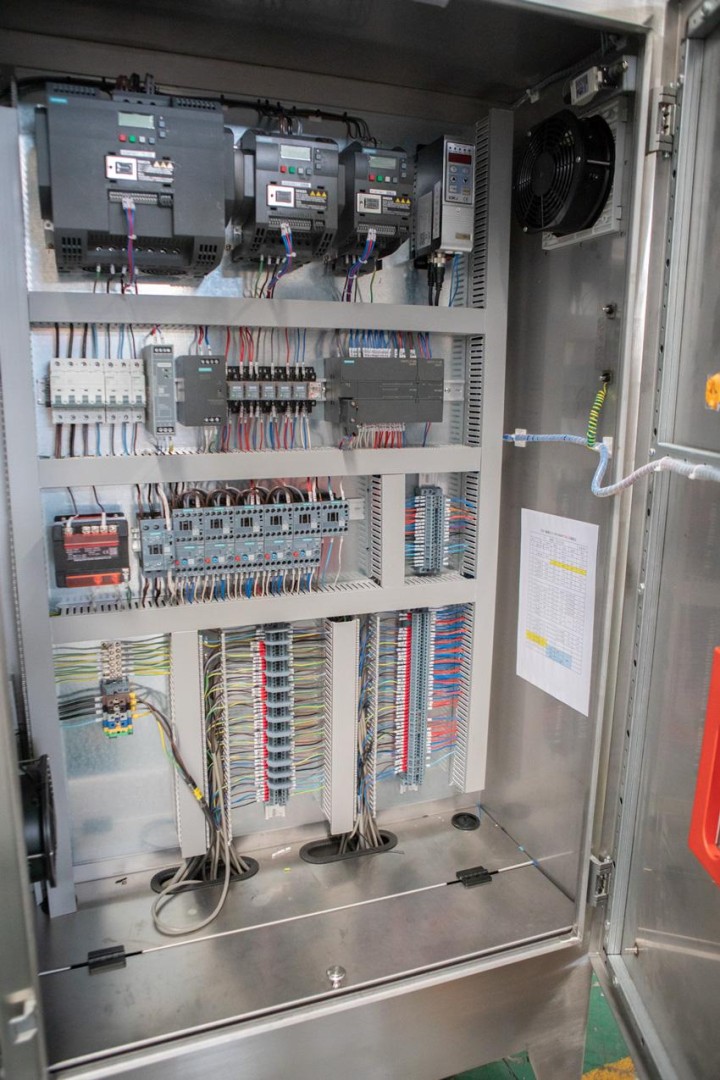

Particular praise was given to the electrical control cabinet of the filling machine. The customer commended the precise, well-organized wiring and layout, noting full compliance with EU electrical safety standards—a clear testament to King Machine’s commitment to quality and international best practices.

Seamless Installation and Commissioning in the UK

By December 2024, the 12,000 BPH sparkling water production line was successfully installed and commissioned in Cornwall, Southwest England. Thanks to thorough planning and on-site technical support from King Machine’s engineering team, the line went live smoothly and has been operating reliably, earning high satisfaction from the client.

This successful delivery highlights King Machine’s proven capabilities in full-line integration, customized engineering, and global project execution.

Proven Success in Global Projects

Beyond the KURE project, King Machine has also undertaken a series of key international projects that demonstrate its technical expertise and global service capacity. For Coca-Cola in Liberia, the company delivered an 18,000 BPH 330ml glass bottle carbonated production line. Z2A BEVERAGE CO. LTD operates a blow-fill-cap 12,000 BPH granular juice hot-filling production line designed for efficiency and product safety. For Dole Philippines, Inc., King Machine supplied a 30,000 CPH 48-head juice can filling machine, supporting one of the world’s leading fruit product brands.

In the Middle East and Africa, King Machine has installed a 3,000 BPH 5-gallon water line for AL-KAWTHER in Saudi Arabia, a 1,200–1,500 BPH 3–5L edible oil filling line for Albaraka in Libya, and a 15,000–18,000 BPH water filling line for Designer Water in South Africa. In Asia, King Machine helped Vikoda in Vietnam set up a 6,000-bottle glass water filling line, while AQUAMIST in Kenya benefits from a reliable 5L water filling line.

These projects highlight King Machine’s ability to deliver tailored solutions across beverages, water, and edible oil, meeting the diverse needs of clients worldwide.

Driving Innovation to Serve Global Markets

As a leading manufacturer in the beverage packaging industry, King Machine has supplied over 1,000 beverage filling lines to more than 90 countries.

In addition to water and beverage filling lines, King Machine also provides a comprehensive range of packaging solutions tailored to diverse industries. Its product portfolio includes can filling lines, weighing oil filling machines, beer filling lines, juice filling lines, and advanced blow-fill-cap machines. This broad product offering enables the company to meet the needs of clients across multiple sectors, ensuring flexibility and efficiency for both small-scale and large-scale production.

The successful completion of the KURE project further reinforces King Machine’s reputation for innovation, quality, and customer-centric service. Moving forward, the company remains committed to advancing intelligent packaging technology and delivering more efficient, reliable liquid packaging solutions worldwide.

Media Contact

Company Name: King Machine

Contact Person: Joyce Xu

Email:Send Email

Phone: +86-13606220224

Country: China

Website: www.king-machine.com